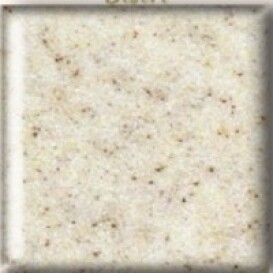

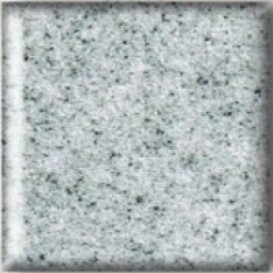

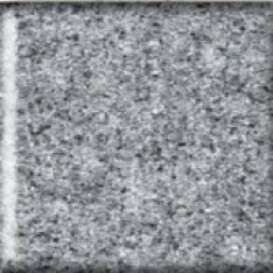

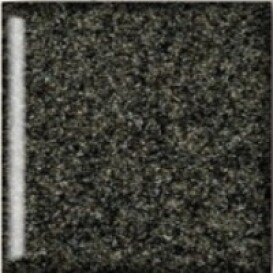

Terrazzinite Decorative Epoxy | Granite Like Appearance | High Build to 3/8″ While Self-Leveling | UV & Abrasion Resistant

Terrazzinite is a high-performance decorative epoxy flooring system designed to create a terrazzo or granite- like appearance in commercial , industrial and residential spaces. This 100% solids, self-leveling epoxy provides a seamless, modern finish that combines aesthetics with durability.

Ideal for showrooms, lobbies, retail spaces, offices ,garages, and hospitality environments. Terrazzinite delivers the upscale look of terrazzo flooring with the chemical resistance, UV stability and strength of epoxy.

The Terrazzinite Epoxy utilizes a cost-effective formula and straightforward application process to achieve the same elegance and beauty of Terrazzo and Granite- a possibility that’s not been realized until now. This self-leveling high build system combines our innovative Terrazzinite powder blend with a two-component, 100% solids clear epoxy binder, producing a cutting-edge formulation that delivers a simple yet stunning alternative to Terrazzo or Granite in one simple application.

Terrazzinite is a two component 100% solids clear epoxy binder, that when combined with the unique Terrazzinite powder, creates an abrasion and UV resistant decorative flooring system. Effortless & uncomplicated, the Terrazzinite System can replace the rigorous, extensive task of traditional Terrazzo installations, while still mirroring the timeless appearance of polished concrete. An easy to apply self leveling formula, it is high build to 3/8″ and looks great while hiding imperfections in your floor .

PRIMER: To reduce chance of concrete outgassing or enhance color saturation, recommend E5015 Water Based Epoxy. and E144 Epoxy Primer . For a high build option or metallics system, consider using the E707LVP Primer.

For applying directly to VCT, ceramic tile, vinyl, linoleum or asbestos mastics, cutback and carpet glues with minimal preparation consider our Perfect Primer Sealer.

TOPCOAT: Optional- depending on the environment, an aliphatic urethane can provide additional chemical resistance and UV resistance. Our 322HW Clear Semi-Gloss Urethane for metallic systems or when applying a clear topcoat to a metallic or flake floor system use E444X Clear High Gloss Polyaspartic for increased UV stability. Many urethane and polyaspartic coatings are acceptable

For Alternative Decorative Terrazzo or Stone looks for your floor, consider using Terrazzo Stone Flakes, Hybrid Stone Flakes or Chipped Stone Flakes.

Where is Terrazzinite Epoxy Used?

- Concrete Countertops & Bars

- Commercial lobbies and office spaces

- Retail stores and showrooms

- Restaurants and hospitality flooring

- Residential garage and basement

- Tables

- Laboratories and Medical facilities

- Shower/Tub Surrounds

- Restroom Partitions

- Hotels

- Retail & Offices

- Locker Rooms

- Cafeteries

- Townhouses

- Apartments

- Bars & Restaurants

Why Terrazzinite Epoxy?

- Stunning Granite-like Appearance

- Smooth Finish and Sleek Design

- Incredibly Easy to Use

- Quicker, Easier and Cheaper than Terrazzo & Granite

- Self-Leveling

- UV Resistant

- High Build t0 3/8″ – 100% Solids Commercial Epoxy

- Good Adhesion 350 psi

- Good Chemical Resistance