No products in the cart.

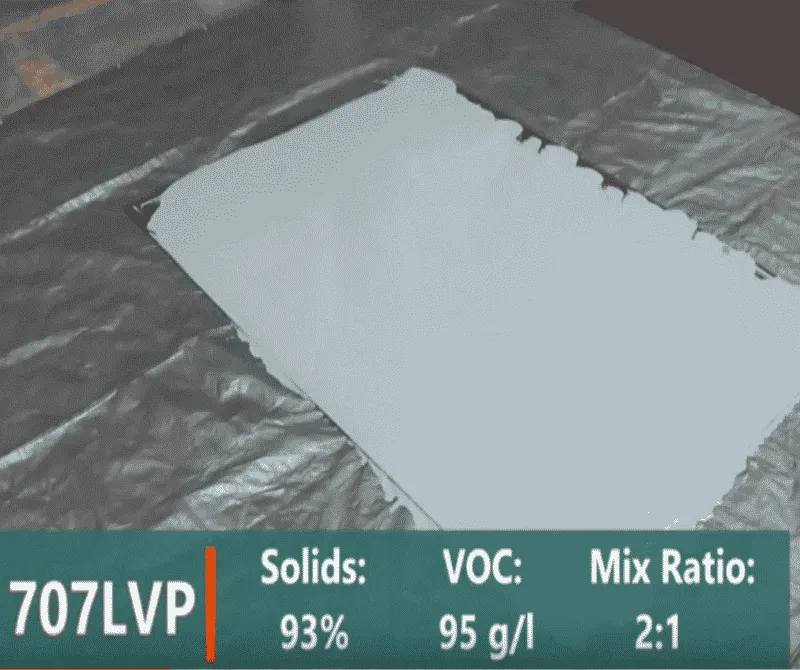

Return To ShopE707LVP High Solids Epoxy Primer & Base Coat

E707LVP is a two component 93% solids epoxy colored coating designed for applications where a high solids penetrating primer is needed before applying 100% solids topcoats for build coats over concrete. Also works great as high solids stand alone epoxy basecoat by itself.

Recommended as primer for high build epoxy systems on concrete or masonry. As a penetrating primer, the E707LVP can be used to help prevent concrete outgassing (bubbles caused by release of air from concrete) from damaging a subsequently applied epoxy basecoat. Product is suitable in many chemical exposure environments.

Available in a wide selection of 20 color options. Comes in quart, 3/4 gallon, 1.5 gallon kits 3 gallon kits and 15 gallon kits.

PRIMER: None required. Recommend the E5015 Water Based Epoxy Primer for very porous surfaces instead of the E707LVP

For applying directly to VCT, ceramic tile, vinyl, linoleum or asbestos mastics, cutback and carpet glues with minimal preparation consider our Perfect Primer Sealer.

TOPCOAT: Many urethane and polyaspartic coatings are acceptable. For companion system, use 707LVP Primer then 707HP High Build Epoxy as an intermediate coat and then topcoat with 322HW Semi-Gloss Urethane for increased UV stability.

E707LVP High Solids Epoxy Used?

- Garages

- Auto Service Centers

- Warehouses

- Laboratories

- Aircraft Hangers

- Cafeterias

Why E707LVP Epoxy?

- High Solids Commercial Grade Epoxy Primer

- Helps reduce problems from concrete outgassing (air bubbles)

- Long POT Life (working time) 35-55 min

- Excellent Adhesion 430 psi

- Good Chemical Resistance

- Wide Variety of 20 Colors

- Great Primer for use with E707HB High Build Epoxy