No products in the cart.

Return To ShopDT-454 Quick Cure UV High Performance Epoxy

DT-454 is a 100% solids, epoxy resin quick cure coating designed to provide superior bonding characteristics with excellent impact, chemical and UV resistance. Withstands up to 9 lbs. of hydrostatic pressure for use in areas susceptible to moisture. Designed as a high performance protective floor coating for a wide range of commercial, industrial and residential projects.

DT-454 should be used wherever a fast curing (6-7 hour re-coat time) durable, high build, protective floor coating is required. DT-454 has no solvent odors and therefore can be used in occupied areas. It’s ideal for both base coats and topcoats in full broadcast systems. It is great for low temperature applications and can be applied down to 40F.

Coverage rate for DT-454 depends on how thick applied. At 100% solids, nothing lost to evaporation after it dries (compare to 50% solids epoxy at big box stores which lose 1/2 of material in container to evaporation). For garage floors recommended 10 mils minimum (160 sq’/gallon) epoxy basecoat thickness. One 3 gallon kit of DT-454 protects most 2 car garages, covering 480 sq’ at 10 mils thick in a one coat application (applied at 160 sq’/gallon).

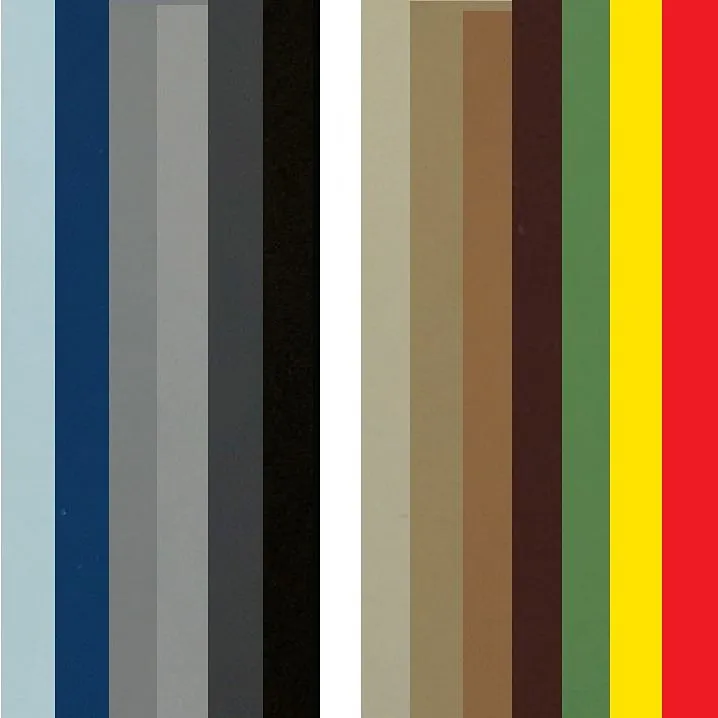

DT-454 comes in clear or can be tinted with one of 13 Pigmented Colors (pigment sold separately by the quart). Pre-pigmented DT-454 available by special order with purchase of 60 gallons or more.

DT-454 is sold in 30 oz sample kits, 3 gallon and 15 gallon kits of clear product.

Apply DT-454 as a base coat at between 10 mils (160 sq/gal)- 16 mils (100 sq’/gal) and with its great durability and UV resistance use as topcoat as needed.

PRIMER: Optional: To reduce chance of concrete outgassing or enhance color saturation, recommend E5015 Water Based Epoxy comes in 20 colors to match topcoat. For quick recoat, one day day project OR application in damp conditions recommend E155CL Epoxy Clear Primer with recoat in 30 min – 1-1/2 hour for 100% solids topcoats and application over damp or moist concrete.

For applying directly to VCT, ceramic tile, vinyl, linoleum or asbestos mastics, cutback and carpet glues with minimal preparation consider our Perfect Primer Sealer.

TOPCOAT: Can apply clear coat of urethane or polyaspartic coating including Aspartic 85 or our 100% solids Aspartic 100.

Where is DT-454 Quick Cure Epoxy used?

- Concrete floors

- Garage floors

- Warehouse, manufacturing and commercial office floors

- Kitchens

- Projects with colder temperatures

Why DT-454 Epoxy

- Tough, Durable Epoxy Coating

- Quick cure 6-7 hour re-coat time

- Outstanding Bonding

- Good chemical, impact and abrasion resistance

- UV Resistance

- Cold temperature application down to 40F

- High solids 100%

- Withstands up to 9 lbs. of hydrostatic pressure

- Available in clear & 14 colors! (Pigment sold separately)