No products in the cart.

Return To ShopMV2112 Moisture Vapor Primer Epoxy

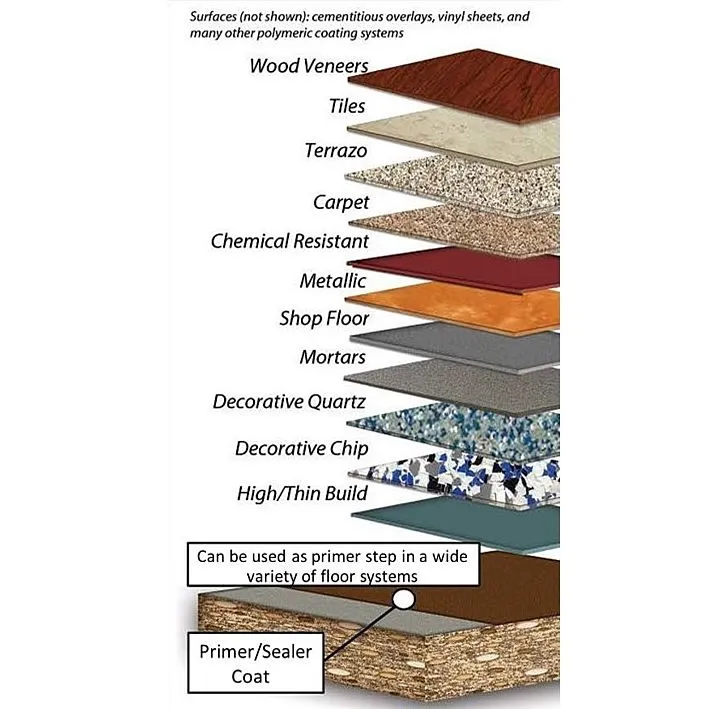

MV 2112 is a 100% solids, two component epoxy sealer that offers superior moisture vapor control, with a perm rating of <.10, which is a Class I Vapor Diffusion Retarder, and rates of up to 20 lb/24hr/1000 ft². May be installed prior to applying Tiles, Terrazo, Wood veneers, polymeric coating systems, Cementitious overlays, carpet, or Vinyl sheets. MVB 2112 meets the ASTM F3010 requirements for vapor permeance at the thickness that’s recommended.

MV2112 is sold in 30 oz trial size kits, 3 gallon and 15 gallon kits of clear (not water clear) product.

PRIMER: None required.

TOPCOAT: MV2112 is designed as primer only and not a stand alone coating. Polymeric coating systems, vinyl sheets, tile, cementitious overlays, terrazo, wood veneers, and carpet

CONSIDERATIONS

- Substrate temperatures must be 5°F above dew point

- Slabs must be at least 4” thick with a functioning vapor barrier

- All new concrete must be cured for at least 10 days prior to application with a minimum compressive strength of 3,500 psi and a minimum tensile strength of 200 psi

- Testing must be performed to confirm a moisture vapor emission rate below 20 lb/24hr/1000 ft² per ASTM F1869 or between 75% and 95% for ASTM F2170

- Product color may vary from batch to batch

Where is MV2112 Moisture Vapor Barrier Primer used?

- Concrete floors

- For use as primer for any coating or resiliant flooring system

Why MV2112 Moisture Vapor Barrier Primer

- Reduce effects of moisture vapor transmission on concrete floors

- Control moisture vapor emission rates to 20 lb/24hr/1000 sq’ (ASTM F1869) or between 75% and 95% for ASTM F2170

- Class I Vapor Diffusion Retarder with Superior moisture vapor control, perm rating of <.10

- Primer to protect Polymeric coating systems, vinyl sheets, tile, cementitious overlays, terrazo, wood veneers, and carpet

- 100% solids with 0 voc

- Meets ASTM F3010 for vapor permeance at the recommended thickness