No products in the cart.

Return To Shop5500 Polyaspartic Polyurea Coating Roll Down Low Temp 30°F | Options To 89% Solids | 5 Set Times | Flexible 120% Elongation

5500 Polyaspartic Coating offers a beautiful, decorative finish while providing a tough durable surface. The 5500 is a low temp waterproof coating that is extremely flexible with 120% elongation, high solids, 2 component, with 5 optional set times that adjust from very cold 30F to very hot and humid conditions 100F+ and 3 solid options from 85% to 89%, aliphatic pure polyurea slow system roll down, self priming for easy application (apply with squeegee then backroll) that can be applied down to 30F. (Note: Recommend using the Fast Set version in cold weather due to slower set times).

Color retention and high chemical resistance with excellent adhesive properties. Highly resistant to staining, tire marking (most tires) and formulated to be color stable, abrasive resistant, non-brittle, flexible, quick set with good impact resistance.

Quick back-in-service times. 5500 fast set version can be walked on in 1 – 2 hours (at 75F). 5500 Polyaspartic Coating can be used as a stand alone system or topcoat to other high performance flooring systems. Available high gloss clear or color. We offer the 5500 Fast Set 20 min (recommended especially for cooler temp down to 30F surface/air), the 5500-EX Slow Set 30 min and the 5500-HH slow set 30 min recommended specifically for high humidity & warm climates, Florida-like).

For projects requiring a primer, suggest the 7001 Moisture Cured Polyurethane which is a quick cure, single component for both concrete and steel projects and is an excellent companion to the 5500 or our E5015 Epoxy Primer which offers 20 colors and a long 1+ hour working time.

5500 is now available in a New Low Odor Version for closed in areas like basements or interior rooms with little or no ventilation. The low odor version comes clear and 5500 Pigment can be mixed in as desired.

For a colorful look, we offer 1/4″ vinyl chips in pre-mixed blended or individual colors. Broadcast chips into either a colored epoxy such as our 6009 Epoxy companion product or use the 5500 as a colored base coat then add clear 5500 top coat.

5500 Polyaspartic Coating coverage rate based on how thick applied. The 5500 at 87% solids, very little lost after it evaporates (compare to 50% solids product from big box stores which lose 1/2 coating to evaporation). For 5 mil thick application, 5500 coverage rate 275 sq’/gallon or 550 sq’ total area with 2 gallon kit when used as a basecoat for basements or light foot traffic only projects. For garage projects, recommend 10 mils minimum base coating thickness. Each 2 gallon kit covers 275 sq’ at 10 mils thick. Can apply up to 10-12 mils thick in a one coat application.

For larger 2 coat projects when using chips/flakes, save money using colored 5500 as basecoat (can broadcast chips/flakes into the basecoat) and clear 5500 as topcoat. Using a clear topcoat over a colored basecoat also adds depth to the visual appearance and enhances the look. Can save even more money on a 2 coat system using our 6009 Epoxy 100% solids as the basecoat and the 5500 Polyaspartic as clear topcoat.

For vertical wall projects, use the 5500V Vertical Wall Polyaspartic. For projects requiring a matte finish, use the 5500M Polyaspartic Matte and for a 100% solids option offering a 1 topcoat solution for full broadcast quartz and silica sand, please see the 5500HS 100% Solids Polyaspartic

COLORANT

When choosing color, colorant shipped separately for mixing into Part A prior to use. Use 10-12 oz colorant to color 1 gallon 5500. If you want Additional Pigment beyond what comes with the 5500, quart containers of 7 different 5500 pigment colors are sold separately if desired. One quart pigment will color 2-3 gallons of 5500 Polyaspartic. Use 10-12 oz pigment per blended gallon of 5500 for most colors. If using white, add 12-14 oz pigment per blended gallon of 5500.

Do not use other pigments with the 5500 as they are not formulated with the proper base materials that are compatible with the 5500. Do not overload the 5500 with pigment, use the minimum amount of pigment for the desired affect.

When using the 5500 as a basecoat on a porous surface and adding pigment, can add up to 4 oz Xylene per mixed gallon 5500 to help with dispersion of the pigment and with penetration into the substrate. Do not recommend adding Xylene otherwise.

5500 Polyaspartic Used?

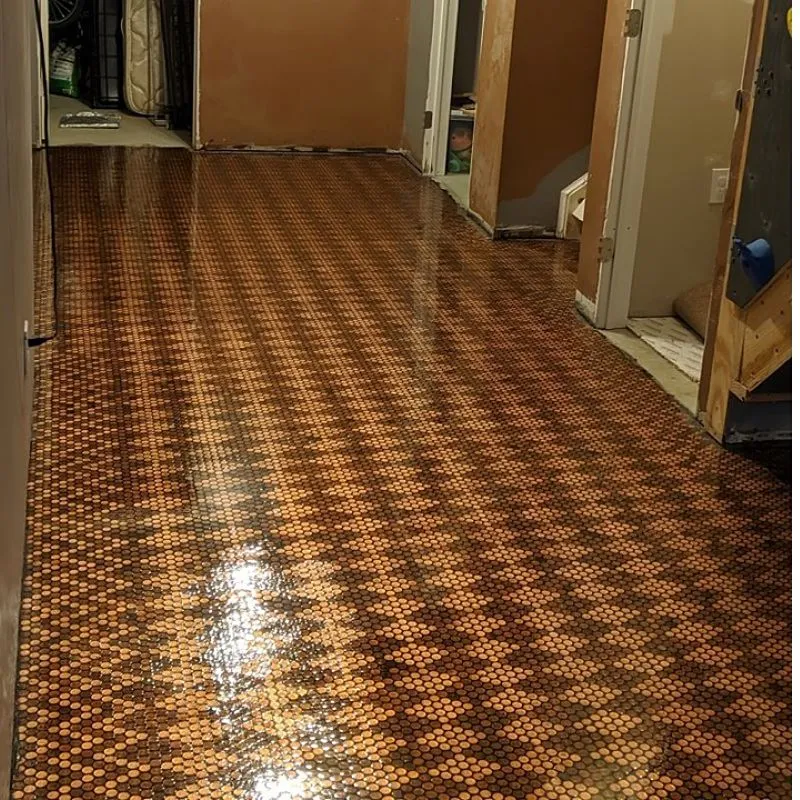

- Decorative Floor Finishes

- Garage floors, basements, offices, showrooms, kitchens

- Industrial Floor Coating

- Water Feature Applications

- Clear Top Coat For Color Chips & Colored Quartz

- Concrete Slabs, Stairs and Pedestrian Walkways

- Decks, Wood Structures

- Interior & Exterior Applications

- Concrete & Wood Countertops

Why 5500 Polyaspartic?

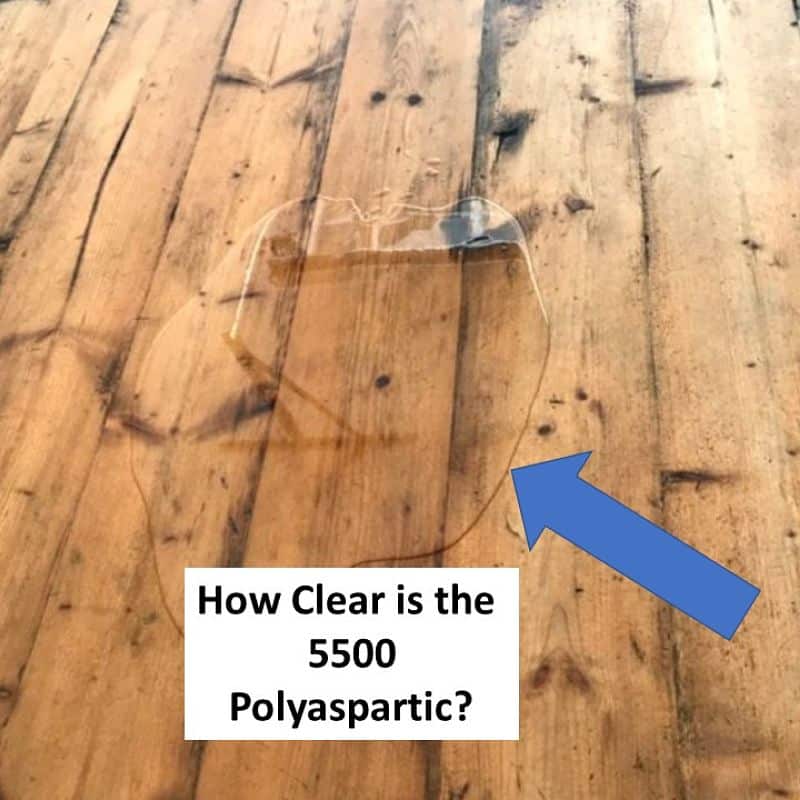

- Beautiful Clear Appearance

- Quick recoat time in as little as 1 – 1.5 hours

- Waterproofing Elastomeric Systems

- Good In Submerged Service Projects Like Fountains

- Works well on concrete, brick, steel, wood, fiberglass

- Outstanding Chemical Resistant

- Excellent Abrasive Resistance

- Excellent flexibility with 120% Elongation

- Highly Adhesive

- Self Priming With No Primer Required

- Excellent Non-Yellowing UV Resistance For Very Clear Finish

- Conforms to the USDA requirements for incidental food contact

- Versatile Options: Fast or Slow Set and 3 High Heat & Humidity options for application up to 100F+

- Cold Weather Apply Down to 30F Using Fast Set Option

- Polyurea performance in an easy to apply roll down formula. Read: basic installation guidelines