No products in the cart.

Return To ShopHyperFLEX Quick Cure Low Temp Epoxy

HyperFLEX is a 100% solids, quick cure, flexible epoxy resin coating membrane designed to provide superior 150% elongation flexibility with extremely rapid cure rates for one day system application. Its outstanding bonding and flexibility properties makes HyperFLEX ideal for wood, concrete, steel (requires primer) deck membranes, joint sealing and crack repair (when mixed with Fumed Silica), small crack bridging, flexible grouts and overlays. It is great for low temperature applications and can be applied down to 40F. Withstands up to 9 lbs. of hydrostatic pressure for use susceptible to moisture.

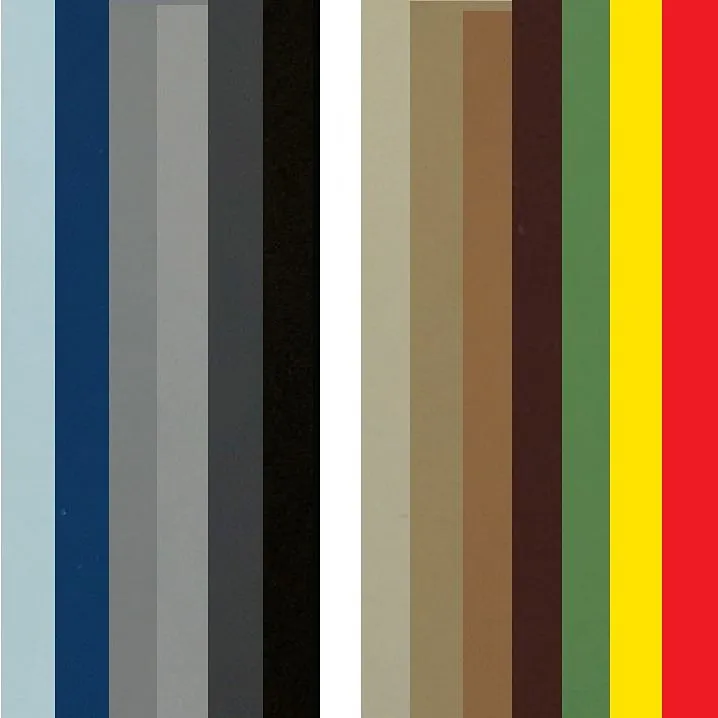

HyperFLEX comes in clear or can be tinted with one of 13 Pigmented Colors (pigment sold separately by the quart). HyperFLEX is sold in 30 oz trial size kits, 2 gallon and 10 gallon kits of clear product. Pigment sold separately in quart containers, amount required depends on color. Pre-pigmented HyperFLEX available by special order with purchase of 60 gallons or more.

Coverage rate for HyperFlex depends on how thick applied. At 100% solids, nothing lost to evaporation after it dries (compare to 50% solids epoxy at big box stores which lose 1/2 of material in container to evaporation). For garage floors recommended 10 mils minimum (160 sq’/gallon) epoxy basecoat thickness.

Apply HyperFLEX as a base coat at between 10 mils (160 sq/gal)- 16 mils (100 sq’/gal). For application over wood surfaces, concrete, steel requiring a flexible membrane or coating, requires application of HyperFLEX clear at 90 sq’/gallon as a base coat with no pigment or chips/flakes added. Can be applied as thick as 50 sq’/gallon for even greater protection. This serves as a base and then you would apply your normal coating system as if the HyperFLEX wasn’t there but just the normal wood, concrete or steel. When HyperFlex used on steel requires a rust inhibiting primer.

HyperFLEX is not UV resistant and not meant to be used without a colored topcoat or full flake broadcast.

HyperFLEX can be used in most any coating project where flexibility is important to project success. It was recently selected for a project to renovate the steel decking on a Frigate owned and operated by the Chilean Navy to help control vibration damage to their non-skid epoxy system being installed from cannon fire from the Main Gun Turret in the bow of the ship. Please click on the Project Link for details.

ONE DAY FULL FLAKE SYSTEM

HyperFLEX can be used by experienced professionals in 70F and above weather as a quick set one day garage, basement and other concrete full chip/flake floor coating system where the goal is “In and out” same day.

To extend working time for the HyperFLEX Epoxy base coat by about 5 minutes, add 5 oz solvent per gallon HyperFLEX (Xylene, MEK, Acetone – use Xylene for best results). This extends working time to about 20 min, typically enough to do a full flake broadcast. Make sure any wet spots that may appear a few minutes after flake broadcast while HyperFLEX is still wet are filled with flakes. Due to the quick curing nature of HyperFLEX, you can walk on the HyperFLEX in only 1 hour (depending on conditions) to complete the project and apply the Aspartic 85 Fast or Aspartic 85 Slow Set Clear Polyaspartic topcoat.

PRIMER: None required. For applying directly to VCT, ceramic tile, vinyl, linoleum or asbestos mastics, cutback and carpet glues with minimal preparation consider our Perfect Primer Sealer. For use on steel, recommend a rust inhibiting primer such as E15M Epoxy Primer

TOPCOAT: Can apply any epoxy, urethane or polysapartic coating system including DT-454, Aspartic 85 or Aspartic 100.

Where is HyperFLEX Quick Cure Low Temp Epoxy used?

- Concrete & wood floors

- Garage floors

- Warehouse, manufacturing and commercial office floors

- Kitchens

- Interior concrete joint and crack repair

- Projects with colder temperatures

- Naval Ship Steel Deck Project to Reduce Cannon Vibration – See ProjectLink

Why HyperFLEX Quick Cure Low Temp Epoxy

- Tough, Durable Epoxy Coating and Flexible Membrane

- Very Flexible with Elongation rating 150% @ASTM D-638

- Great for Quick Crack Repair and Control Joint Filler (when mixed with Fumed Silica)

- Can be used as a (1) basecoat for full broadcast floors, (2) flexible membrane, (3) repair gel to fill joints, cracks, & divots

- Superior Flexibility and Outstanding Bonding

- Cold temperature application down to 40F

- Rapid Cure Rate For Same Day Flake and Solid Color System Application

- When used as membrane or basecoat HyperFLEX cures about 2 hours

- When used for fumed silica gel repair cures about 10-15 minutes

- Good chemical and abrasion resistance

- High solids 100%

- Withstands up to 9 lbs. of hydrostatic pressure

- Available in clear & 13 colors! (Pigment sold separately)