No products in the cart.

Return To ShopGroundWorx Ultra ESD Static Conductive Heavy Duty 100% Solids Epoxy Primer | ANSI/ESD S20.20-2014

GroundWorx Ultra (Formerly HB-97.2) ESD Conductive Epoxy Primer is a two-component 100% solids high build epoxy resin moisture tolerant coating system that can be applied as a clear or pigmented floor primer or coating. It is designed specifically to be used as an ESD conductive primer prior to application of the GroundWorx Ultra ESD Urethane Topcoat as a heavy wear ESD protective coating system in a wide variety of heavy duty commercial and industrial environments where the harmful effects of electrostatic discharge must be avoided.

The GroundWorx Ultra epoxy when used with the GroundWorx Ultra Urethane Conductive topcoat has an electrical resistance of <1.0 x 10e6 ohms limiting Static Charge Generation to <15 volt. When used with the Dissipative version of the GroundWorx Ultra Urethane topcoat the system has an has an electrical resistance of >1.0 x 10e6 ohms and <1.0 x 10e9 ohms limiting Static Charge Generation to <15 volt.

When used together, the GroundWorx Ultra ESD Urethane Topcoat and GroundWorx Ultra ESD Epoxy Primer Coat complete an ESD protection, static control system that can be used where significant commercial and industrial forklift, pallet jack, heavy cart and foot traffic is present at less than $4.00/sq’ material cost (delivered).

PRIMER: For applying directly to VCT, ceramic tile, vinyl, linoleum or asbestos mastics, cutback and carpet glues with minimal preparation consider our Perfect Primer Sealer.

The GroundWorx Ultra ESD system meets ESD Association (ESDA) standards and is compliant with ANSI/ESD S20.20-2014 recommendations for grounded static-control flooring.

Recommended for use on concrete, wood and old VCT floors. Comes in a gloss finish. The GroundWorx Ultra ESD Primer is moisture tolerant and can be applied to a floor <75% relative humidity. The GroundWorx Ultra ESD system offers easy maintenance and never requires waxing or buffing.

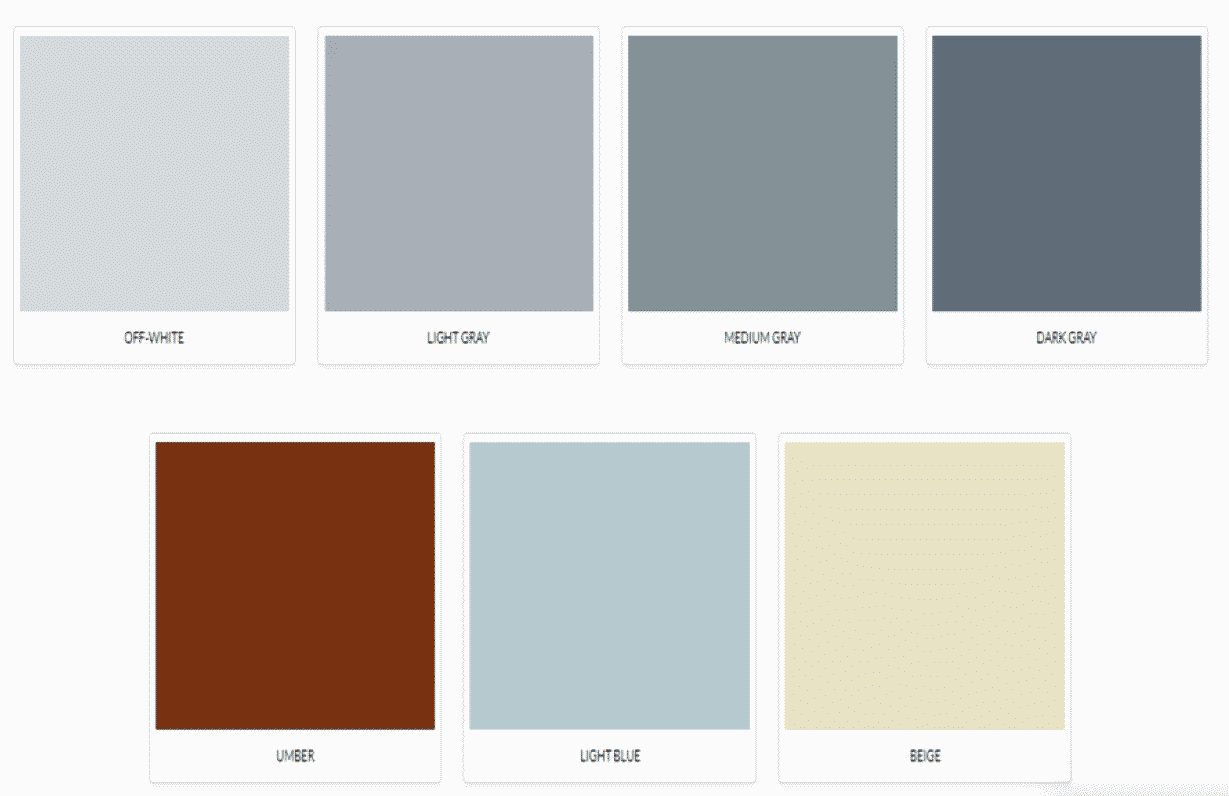

Available in a 3 gallon kit and 8 standard colors. Custom coloring available on special order basis to meet your specific color matching requirements.

Recommended minimum coverage rate for GroundWorx Ultra Epoxy Primer is 160 sq’/gallon (10 mils thick) for great performance up to as much as 20 mils thick in one coat for extremely heavy traffic systems.

We also offer the option to include a Two-inch-wide copper grounding strip for grounding to earth grounds. Copper is 1.4 mil thickness (2.6 mil thickness with the conductive adhesive backing). Recommend at least 1 grounding strip every 1,000 sq’ of project surface area. Copper grounding strip to be applied OVER the GroundWorx Ultra Epoxy Primer/Basecoat BEFORE application of the GroundWorx Ultra Urethane Topcoat See the guide: HOW TO GROUND ESD COATINGS

For more information on anti-static floor systems, see our video library.

Where is the GroundWorx Ultra ESD Conductive Epoxy Primer used?

- Electronics manufacturing & assembly areas

- Research & Development

- Computer storage and warehousing areas

- Component Testing and Repair

- Warehouse Areas

- For Heavy Duty Forklift and Pallet Jack Traffic Areas

Why GroundWorx Ultra ESD Primer?

- Static dissipative or conductive high build epoxy electrical protection when used with the GroundWorx Ultra ESD Urethane Topcoat, which comes in either dissipative >1.0 x 10e6 ohms or conductive <1.0 x 10e6 ohms electrical resistance, limiting Static Charge Generation to <15 volts

- Great for high traffic, high wear commercial & industrial applications as high build 14 mil ESD system at <$4.00/sq’ material cost

- Great for high traffic, high wear commercial & industrial applications

- Use on Concrete, Wood and old VCT surfaces

- Moisture tolerant primer

- Excellent adhesion 350 psi

- 100% solids, 0 g/L voc

- Conforms to ESDA, ANSI standard S20.20-2014

- Gloss sheen

- 8 standard colors

- Full range of custom Colors available on special request