No products in the cart.

Return To Shop6700 ESD Premium Static Dissipative Anti-Static Paint

6700 ESD Vinyl Paint Plus is a static dissipative water based acrylic vinyl coating to use in static controlled environments. Comes in 9 different colors with a durable, low sheen finish. Static Dissipative in the range of 10e7 – 10e9 ohms. Conforms to ANSI/ESD S20.20-2014 when tested according to ANSI/ESD STM7.1

For static conductive requirements, see 6700 ESD Static Conductive Paint.

Custom colors to meet your requirements also available on special order. Recommended for use on properly prepared interior concrete floors, but can also be applied to walls, wood and metal surfaces. Features good resistance to abrasion, oils and washing

Available 1 gallon and 5 gallon pails and in 9 colors: White, light gray, medium gray, dark gray, black, blue, green, biege, safety yellow. Full range of custom colors available on special order to meet your specific color matching requirements.

PRIMER: For applying directly to VCT, ceramic tile, vinyl, linoleum or asbestos mastics, cutback and carpet glues with minimal preparation consider our Perfect Primer Sealer.

TOPCOAT: Optional: None required. For additional physical protection as a low cost sacrificial option, use the 4000 Acrylic Static Dissipative Clear Floor Finish

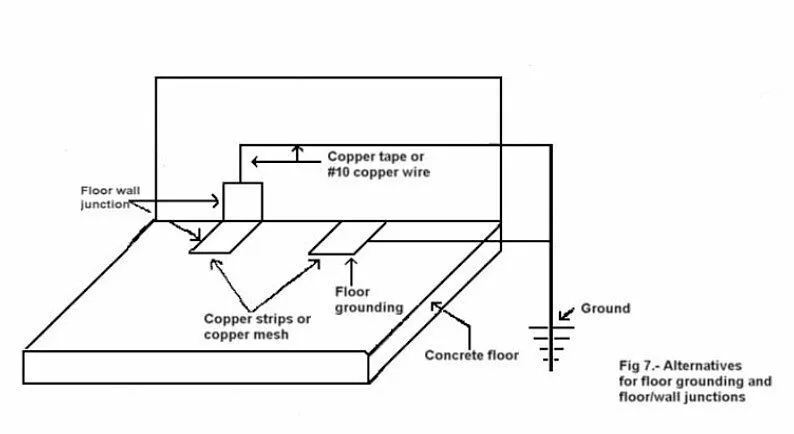

We also offer the option to include a Two-inch-wide copper grounding strip for grounding to earth grounds. Copper is 1.4 mil thickness (2.6 mil thickness with the conductive adhesive backing). Recommend at least 1 grounding strip every 1,000 sq’ of project surface area. See the guide: HOW TO GROUND ESD COATINGS

For floor surfaces subject to heavy wheeled traffic use including forklift and pallet jack traffic, we offer our GroundWorx Ultra Coating System which includes a high performance 2 part 100% solids epoxy basecoat and high solids urethane topcoat for excellent ESD anti-static control in a physically demanding environment.

For more information on anti-static floor systems, see our video library.

Where is the 6700 used?

- Electronics manufacturing and assembly, ESD protected environments

Why 6700 ESD Paint?

- Static dissipative 10e7 – 10e9 ohms

- Conforms to ANSI/ESD S20.20-2014 when tested according to ANSI/ESD STM7.1

- No hot spots

- Excellent adhesion and color retention

- Good resistance to abrasion, oils and washing

- Use on Concrete, Wood, Metal surfaces

- Interior or exterior use

- Non-hazardous, low VOC

- Non-flammable

- Low gloss sheen

- 9 in-stock colors

- Full range of custom Colors available on special request