No products in the cart.

Return To ShopE591 / E590 100% Solids Wet Surface Epoxy Coating | Apply Underwater | Low Temp 35F

E591 and E590 are 100% solids, two component Cycloaliphatic Epoxy Coatings that may be applied on wet surfaces with standing water or underwater without effect on cure. Works on concrete and steel for both vertical walls and horizontal floor surfaces. E591 and E590 provide very low permeability along with excellent impact and abrasion resistance.

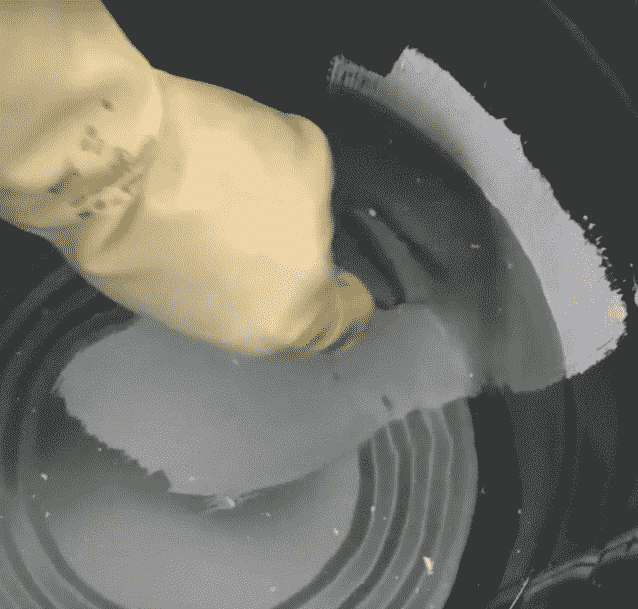

The E591 is a lower viscosity epoxy for easier spreading and application in above water projects. The E590 is a significantly higher, thicker viscosity and offers easier application in difficult underwater applications where you are applying below the water line. The thicker viscosity of the E590 allows for quicker and easier underwater application as it more easily displaces water than the thinner E591. For easiest application underwater use our Tampico Surface Preparation Kalsomine Brush.

When used above water, even in 100% RH concrete, the E591 is the best option due to its thinner viscosity and easier ability to be rolled. Both the E591 and E590 offer identical technical performance specifications.

Formulated with a unique moisture insensitive polymer for use in wet conditions from both fresh and salt water. Inclement weather will seldom interfere with paint schedules. Recommended for steel and concrete surfaces. E591 and E590 are made with a special resin modification that produces a flexible film, making them ideal for painting over existing sound paint without “lifting”.

Can apply on vertical surfaces to 12 mils thick in one coat (135 sq’/gallon) and on floors up to 20 mils thick in one coat (80 sq’/gallon). When mixed with a blend of silica flour and sand, E591 may be used to repair underwater, or below grade leaks in steel or concrete structures.

Can be used in submerged service applications with proper preparation and coverage rates followed. Low temperature application to 40°F on steel and 50°F on concrete and cures down to 35°F (must remain at application rated temperature for at least 1 hour before falling as low as 35°F) .

E591 and E590 are not designed for applications with hydraulic vapor pressure problems (water pressure coming through negative side or underneath coating)

E591 Epoxy and E590 Epoxy are available in 1 gallon kits and 52 gallons (52 gallons ships in (13) 4 gallon kits LTL Freight to commercial location only). Comes in 4 colors: Light Gray, Medium Gray, White and (Dark Gray – special order min order 35 gallons). Each 1 gallon kit of E590/E591 kit is also available with (1) Tampico Surface Preparation Kalsomine Brush for easier application in underwater projects.

Recommend 2 coat application with each coat at 8 mils (200 sq/gallon) to 20 mils (80 sq/gallon) for total application thickness 16 to 40 mils. E591 has a long working time 40 – 50 minute POT life at 75F and E590 has a shorter POT life of 20-30 min.

For crack and hole repairs underwater prior to applying the E591 Epoxy consider our underwater Mend-Con RTU Epoxy Repair product.

Where is the E591 & E590 used?

- paper and pulp mills

- chemical processes

- waste water treatment facilities

- fertilizer plants

- electric generating stations

- ore recovery facilities

- mining sites

- refineries

- dairies

- laundries

- dams

- marine environments such as pilings

- submarine pens

- wet ends of paper machines

- bleach plants

- manholes

- pits

- sumps

- cooling

- towers

- clarifiers

- piers

- underwater applications, etc.

- all kinds of wet processes

Why E591 & E590 Coating?

- May be applied on wet or under water surfaces

- Self-priming on steel and on most concrete applications

- Cold temperature cure down to 35F

- Ideal for marginally prepared and painted surfaces

- Outstanding impact and abrasion

- High film build – Up to 20 mil DFT per coat on horizontal surfaces

- Vertical surfaces to 12 mils

- Excellent coating for manholes

- 100% solids and 0 g/L VOC’s

- 3 Colors Available