No products in the cart.

Return To ShopProduct Description

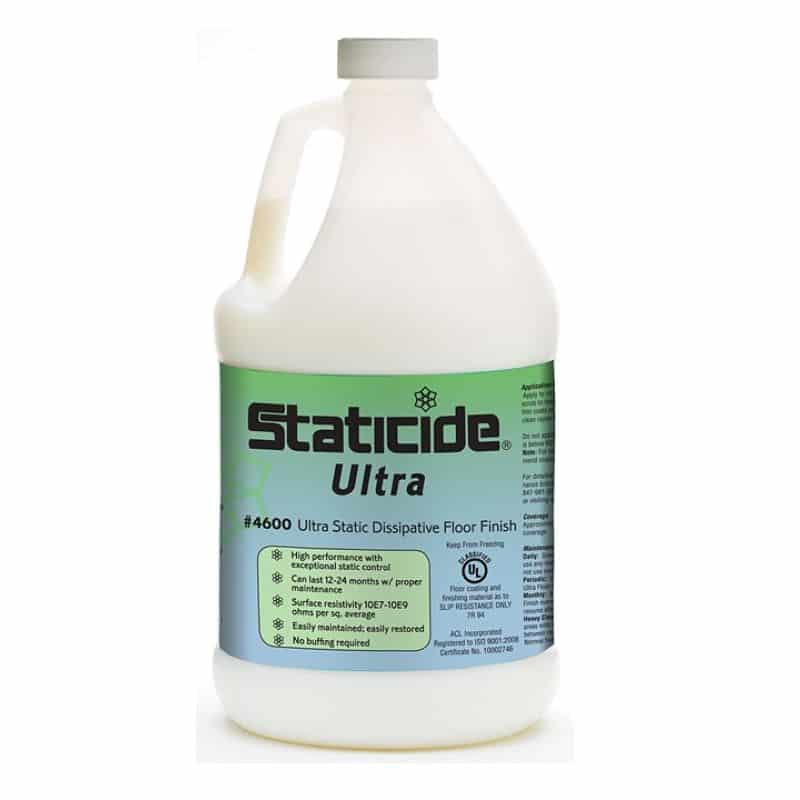

4600 Ultra Static Disspiative Floor Finish

No other ESD floor finish can match Staticide® 4600 Ultra Floor Finish for electrical properties, physical longevity, and gloss. This urethane-enhanced formula features superior abrasion resistance and durability, fortifying floors with a long-lasting protective layer that is shiny and ESD-safe for 12 to 24 months. By maximizing stripping cycles, companies can keep costs down by eliminating annual labor fees and production shutdowns.

4600 is easily maintained and repaired with no buffing, extending the stripping/recoating cycle. 4600 utilizes the latest technological advancements in static dissipative polymers, setting a whole new standard for performance and value. This enhances its static controlling powers and maximizes its effectiveness on your floors. Resistivity is 10⁸ – 10⁹ ohms per square and static dissipationn is .02 seconds. Staticide® Ultra Floor Finish is the perfect choice for any environment where static control is required, such as electronic, medical, and clean room manufacturing facilities. For use on vinyl, linoleum, or ceramic tile

This water-based formula is UL listed for slip resistance, RoHS compliant, biodegradable, non-flammable, and free of formaldehyde, phthalates, alkalis, acids, and ammonia.

Where is 4600 typically used?

- Electronics manufacturing and assembly, telecommunications, ESD protected areas, medical, clean room manufacturing facilities

Why 4600 Static Dissipative Floor Finish?

- High performance with exceptional static control

- For Use on vinyl, linoleum, or ceramic tile

- Offers high gloss, slip resistant & abrasion resistant finish

- More economical than other leading ESD floor finishes

- Resists powdering or flaking, even in dry condidtions

- Resists scuffs, will not yellow

- Controls static generation even at low relative humidities

- Low volatile organic compounds (V.O.C’s)

- Dries faster and with higher gloss intensity than other ESD finishes

- Compliant to ANSI/ESD S20.20-2007

- Biodegradeable, Non toxic