No products in the cart.

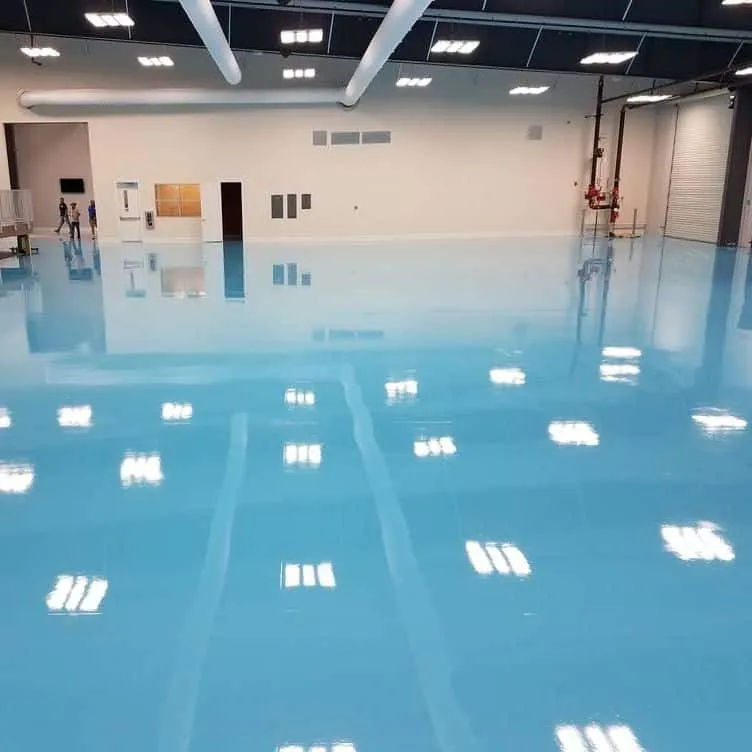

Return To ShopE352P Hi-Gloss Polyester Polyurethane Floor Coating | Chemical Abrasion Resistant | Exterior Interior

A two component polyester aliphatic isocyanate polyurethane coating. This special CRU formulation is used to impart the highest chemical resistance, gloss and color retention of a polyurethane coating, yet retain the outstanding tough, abrasive resistant film which provides excellent exterior durability, chalk resistance, color stability and long term gloss retention.

Ideal for use as a clear or pigmented topcoat in both interior and exterior Industrial, Commercial and Marine applications. Not for use directly on unprimed surfaces and not designed for submerged service. Can be applied to existing epoxy, polyaspartic or urethane coatings (do not apply to acrylic paint) after proper preparation including sanding and wiping with acetone solvent right before application (apply E352P as soon as acetone solvent is dry).

The clear E352P-CLR is is ideal as a final clear top coat for color quartz, vinyl/acrylic chip decorative floors, pigmented epoxy and polyurethane coatings, epoxy slurries/mortars, interior wood, brick and warehouse floor coatings.

For vertical topcoat applications suggest our E370P Hi-Gloss Polyurethane.

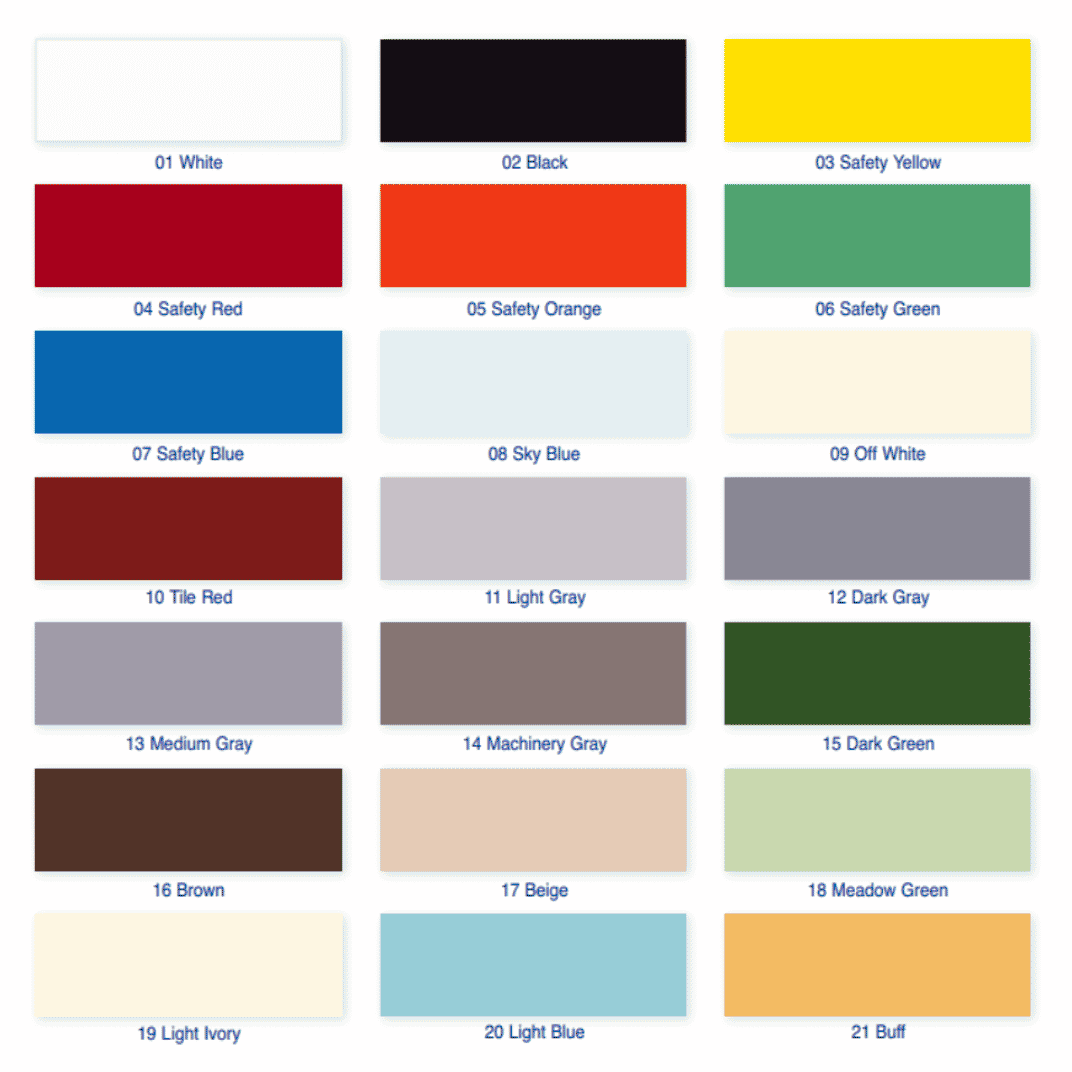

Available in 1.5 gallon kit and 15 gallon kit (15 gallon kit special order only) with mix ratio 2:1 by volume (2 parts Base Part A to 1 part Hardener Part B). Comes in clear and 11 colors including full range of safety colors. Long 4 hour POT life @ 75ºF.

Apply at 2.0-3.0 dry mils per coat, Pigmented 320-480 sq’/gallon, Clear 290-440 sq’/gallon

Application using a lambs wool application, short nap roller or brush.

PRIMER: Recommend the 5015 Water Based Epoxy Primer and for heavier duty or steel applications the E15M Epoxy Mastic Primer. Do not apply to unprimed surfaces. Can be applied to existing epoxy, polyaspartic or urethane coatings after proper preparation including sanding using 100 grit and wiping with acetone solvent right before application (apply E352P as soon as acetone solvent is dry).

TOPCOAT: Can apply multiple coats of the E352P

Where is the E352P Polyester Polyurethane used?

- Garage floors

- Warehouse floors

- Production floor areas

- Aircraft hanger floors

- Factories

- Assembly plants

- labs

- institutions

- chemical processing plants

- power plants

- dairies

- pulp and paper mills

- sewage and waste water treatment facilities

- fertilizer plants

- petroleum refineries

- electric generating stations

- coal handling operations

- marine installations,

Why E352P Polyester Polyurethane Coating?

- Great Interior & Exterior Horizontal Concrete & Steel Protection

- Exceptional Exterior Durability

- Excellent weather resistance

- Non-chalking and non-yellowing

- Excellent gloss and color retention

- Extremely tough, yet flexible

- A tile-like finish.

- Easy to clean

- Excellent chemical and stain resistance

- Highly resistant to abrasion and impact

- Outstanding wearing properties

- Handles up to 250°F Dry Service

- Long 4 hour POT life @ 75ºF

- Available in clear and 11 colors