No products in the cart.

Return To ShopAspartic 85 Slow Set Polyaspartic | Low Temp 30°F | Low Odor Option

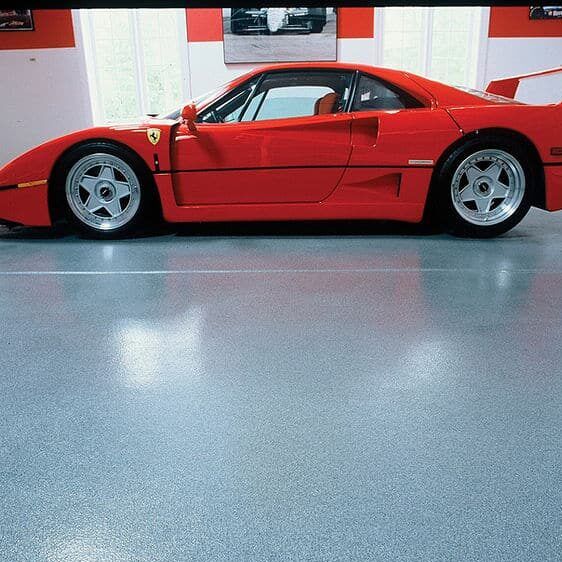

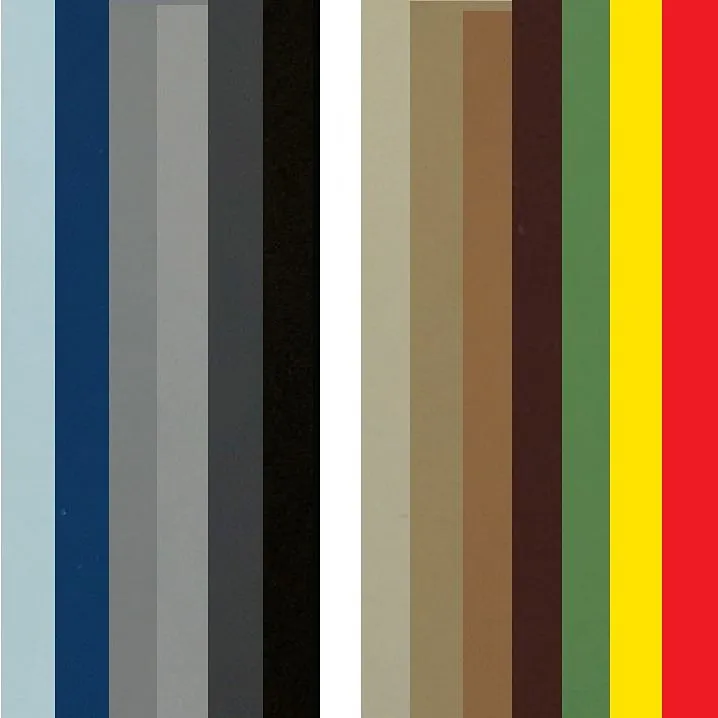

Aspartic 85 Slow Set is a two component, 85% solids, solvent based low temp polyaspartic aliphatic coating designed as an extremely tough, durable and decorative topcoat to protect high performance epoxy floor concrete coating systems. Aspartic 85 Slow Set offers excellent abrasion and chemical resistance, is UV Stable, and has a beautiful, extremely clear, high gloss appearance available in 14 colors and a new LOW ODOR option! Long 45-60 minutes working time for easier application.

Offering quick back in-service times, Aspartic 85 Slow Set Is A Slow Curing Polyaspartic Solution To Allow More Working Time And Yet Still Allows Quicker Back In Service Times Than Traditional Epoxy Or Urethane Coatings. Aspartic 85 Slow Set Can Be Applied In Cold Weather Down To 30°F (cold temperatures will significantly slow down recoat and back in-service times).

The spread rate of the Aspartic 85 Slow Set over a Metallic System is 500-600 sq.ft. per gallon, as a clear topcoat over a smooth surface apply at 500 sq’/gallon and as a pigmented topcoat over a smooth surface apply at 400 sq’/gallon and over a full broadcast flake floor, it is 130-160 sq.ft. per gallon.

Aspartic 85 Go Slow is sold in 30 oz trial size kits, 3 gallon and 15 gallon kits. It comes in clear or can be tinted with one of 14 Pigmented Colors (pigment sold separately by the quart). New LOW ODOR version now available when using indoors with minimal ventilation. Pre-pigmented Aspartic 85 Go Slow available by special order with purchase of 60 gallons or more.

Aspartic 85 Go Slow is also available in a faster setting version, Aspartic 85, for even quicker back in-service and faster recoat times.

Aspartic 85 So Slow is not recommended for application direct to concrete but designed for application over interior epoxy systems with solid colors, flakes and quartz granules. Not recommended for outdoor projects.

PRIMER: Recommended as topcoat to high performance epoxy systems

TOPCOAT: None recommended. Can apply multiple coats of Aspartic 85.

Where is Aspartic 85 Go Slow Polyaspartic used?

- Concrete floors

- Warehouse and commercial office floors

- Kitchens

- Projects with colder temperatures

Why Aspartic 85 Go Slow Polyaspartic?

- Tough, durable topcoat for interior epoxy floor coatings

- Cold weather application down to 30°F

- Excellent chemical and abrasion resistance

- UV Stable and will not yellow

- Beautiful high gloss appearance

- Benefits Of A Polyaspartic With Longer 45-60 minutes Working Times

- Designed for high traffic and industrial areas

- High solids 85%

- Available in clear & 14 colors (pigment sold separately)!

- LOW ODOR version now available for indoor projects.