No products in the cart.

Return To ShopE-Green Polyurea Basecoat for Concrete Floors | Low Temp 40°F | 100% Solids | 300% Elongation

E-GREEN is flexible two component 100% solids, plant-based Polyurea coating that is environmentally friendly and VOC Compliant. E-GREEN exhibits superior bonding properties, has virtually no odor, and has fantastic viscosity, exhibiting amazing workability. Because of its supreme flexibility, when used as a basecoat, the floors will have exceptional chip and impact resistance. E-GREEN is ideal for one day systems because of its fast cure rate. Not recommended as topcoat as not UV stable or where moisture is present during application and curing.

E-Green Polyurea is an extremely flexible, tough, durable and impact resistant basecoat with little to no odor. Recommended for any area that requires a highly flexible primer and/or fast-curing primer or base coat. Can be also used as a quick cure basecoat for a full broadcast chip/flake or quartz broadcast system as well as when topcoated with a a solid color coating.

With 300% elongation, great for use as a flexible membrane on floors that flex including wooden floors. When used on wooden floors suggest first applying a penetrating epoxy primer designed for bonding to wood surfaces such as our E5015 Epoxy Primer then apply the E-Green Polyurea at rate of 100 sq’/gallon.

E-Green Polyurea can be applied in cold weather down to 40°F. (cold temperatures will significantly slow down recoat and back in-service times). Additionally, E-Green is available in a specially formulated Summer Blend that offers longer (up to 45 minutes) working times and a 1-2 hour cure in hot summer temperatures.

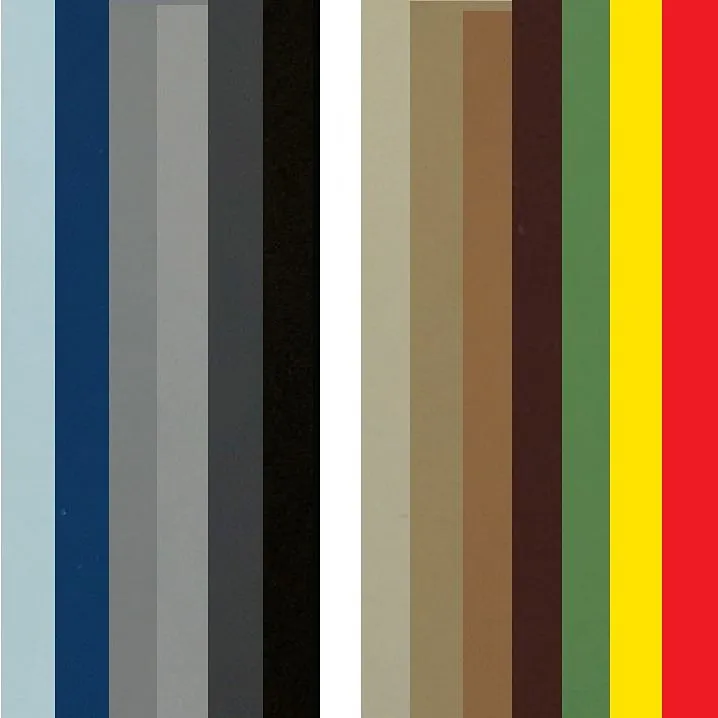

E-Green Polyurea is sold in 30 oz sample kit, 3 gallon and 15 gallon kits. It comes in clear or can be tinted with one of 14 Pigmented Colors (pigment sold separately by the quart). READ MIXING INSTRUCTIONS ON APPLICATION TAB AS THIS PRODUCT REQUIRES CAREFUL ATTENTION TO MIXING, POURING, SQUEEGEE TIMES FOR GOOD RESULTS

The spread rate of the /E-Green Clear as a clear topcoat over a smooth surface apply at 300 to 350 sq’/gallon and as a pigmented topcoat over a smooth surface apply at 250 to 350 sq’/gallon and over a full broadcast flake floor, it is 130-150 sq.ft. per gallon. Can be applied as thick as 16 mils or 100 sq’/gallon in one coat.

PRIMER: If desired can use the E5015 Epoxy Primer

TOPCOAT: Most any solid color epoxy, polyaspartic or urethane

Where is E-Green Low Temp Polyurea used?

- Garages

- Basements

- Concrete floors

- Warehouse and commercial office floors

- Kitchens

Why E-Green Low Temp Polyurea?

-

- Tough, durable plant based Polyurea Coating

- Extreme Flexibility (300% Elongation)

- Exceptional Adhesion >500 psi ASTM D4541

- Cold temperature application down to 40°F

- Can be used as high build basecoat up to 16 mils or 100 sq’/gallon

- Excellent chemical and abrasion resistance

- Designed for high traffic and industrial areas

- 100% Solids Performance

- Available in clear & 14 colors!

- Quick Cure 1 Day System

- Little to NO ODOR