No products in the cart.

Return To ShopE28 Cool Life Deck Coating | Infrared Heat Reflective Technology in 12 Colors | 100% Acrylic | Concrete Wood Masonry Metal | Chemical Resistant

Keep your feet from burning on the pool deck this summer with the E28 Cool Deck Coating. This 100% Heat Reflective Coating available in 12 colors is specially formulated to reflect infrared rays, and can reduce a colored deck’s surface temperature up to 25-30%!

Perfect for balcony decks, walking decks, pool decks, walkways, patios roofs and other walking surfaces subject to extreme heat, the E28 Cool Life also provides resistance against water, alkalis, acids, ultraviolet light and staining.

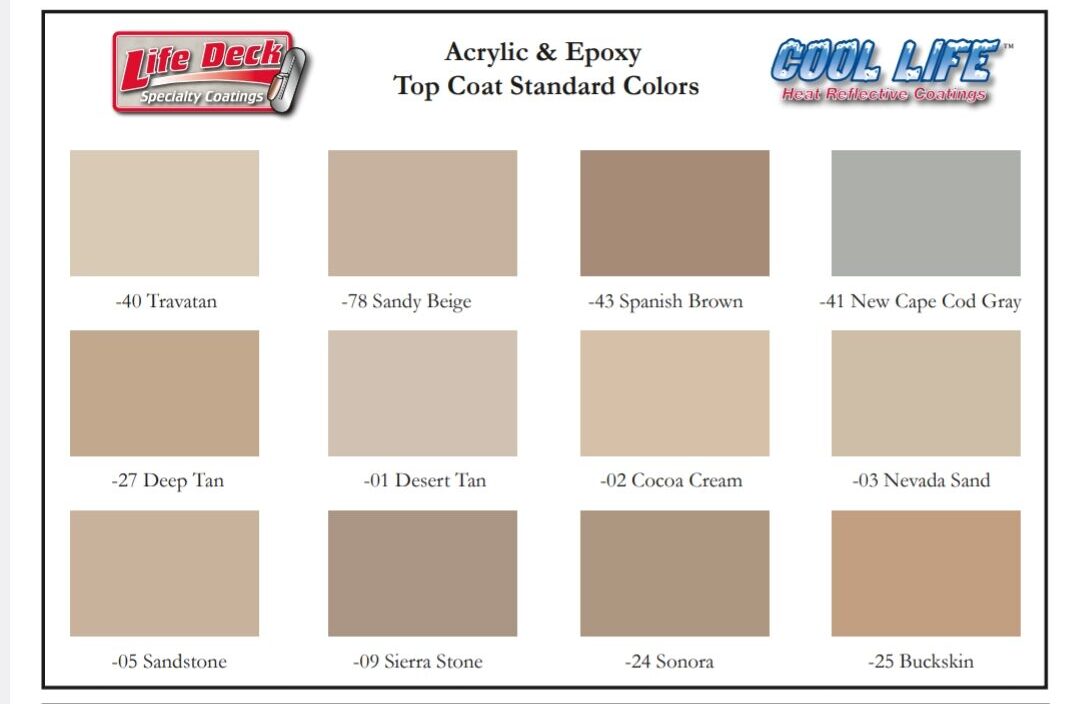

Using special infrared reflecting and heat reducing pigments, the E28 Cool Life Deck Coating provides dramatic cooling benefit in 12 different pre-tinted colors (see performance chart below).

E28 Cool Life Deck Coating is also great for sealing concrete, masonry and wood to provide resistance against water, alkalis, acids, ultra-violet light and staining. Used for concrete and wood floors, pool decks, patios, and Textured Concrete. Not designed for vehicular traffic.

Available in 1 Gallon & 5 gallon containers.

Primer: Recommend primer for unpainted surfaces, suggest our E25 Primer or E7075 100% Acrylic Primer

Topcoat: None required. Recommend 2 coats E28 Cool Life Deck Coating for heavier traffic use and longer lasting applications.

WHERE IS E28 COOL LIFE HEAT REFLECTIVE COATING USED?

- Pool Decks

- Concrete Floors

- Patios

- Balcony Decks

- Walking Decks

- Roofs

- Concrete, Masonry, Wood and Painted Steel Surfaces

WHY E28 COOL LIFE HEAT REFLECTIVE COATING?

- Up to 25-30% Reduction in Surface Temperature using one of 12 colors available

- Infrared Heat-Reflective Technology

- Great for Pool Decks, Patios, Porches Concrete, Masonry, Wood

- UV Resistant

- Slip resistant surface – passes ASTM D2047-82

- Excellent Hide & Color Retention

- Resistant to Ponding Water

- Light Chemical Resistant

- Alkali & Moisture Resistant

- Fast Drying

- Easy to Clean

- Water based – low voc