Product Information

$107.00 – $680.00Price range: $107.00 through $680.00

- Heavy duty non-skid resistance for concrete & steel

- Available in regular cure and cold temp formula to 25°F

- Designed for wet areas

- Meets ADA and OSHA requirements for safe co-efficient of friction (COF) when properly applied

- Meets Navy Military Specification Mil-PRF-24667B for Non-Skid Deck Coatings

- Excellent adhesion, abrasion and impact resistance

- Resistant to grease, oil, salt water, alcohol, detergent, gasoline, hydraulic fluid

- Excellent coating for Diamond Plate

- Easy to apply, ready to use non-skid coating

- Comes in 4 colors

- E651 Non-Skid Epoxy Version Available with ZERO VOC

You may also like...

E1016 Anti-Slip Epoxy Concrete Floor Coating - 3 Gal Kit | 20 Colors | Tennis Court Like Surface

Aluminum Oxide Anti-Slip | WHITE | 4 Grit Sizes | Non-Skid Tough Durable Floor

EZ-Coat Textured Acrylic Coating | Metal, Wood, Concrete | Textured Finish | Scratch Resistant

- Overview

- Gallery

- Specs

- Coverage Rate

- Cure

- Chemical

- Application

- Video Install

- Customer Projects

- More Options

E650 Heavy Duty Non-Skid Epoxy Floor & Deck OSHA ADA Navy Spec MIL-PRF-24667B Type 1 | 4 Colors | Zero VOC Option

E650 is a two component heavy duty non-skid epoxy floor & deck coating with excellent adhesion, abrasion and impact resistance over concrete and steel surfaces. E650 provides slip resistance in wet and slippery conditions with an aggressive anti-slip profile that offers safer footing and traction on concrete and steel surfaces in interior and exterior industrial and marine environments.

The E650 Meets Navy Military Specification Mil-PRF-24667B Type 1 (High Durability, Rollable Deck Coating) requirements for safe co-efficient of friction (COF), ADA and OSHA anti-slip protection guidelines when properly applied.

Available in 1 gallon kit and 40 gallons (ships in eight 5 gallon kits LTL Freight to commercial location). Available in regular cure with a long 1-1/2 hour POT Life and low temp version which can be applied down to 38°F and will cure down to 25°F (has to remain at/above 38°F for at least 1 hour after application).

E651 Non-Skid Epoxy with Zero g/L VOC version is available with same specifications as the E650.

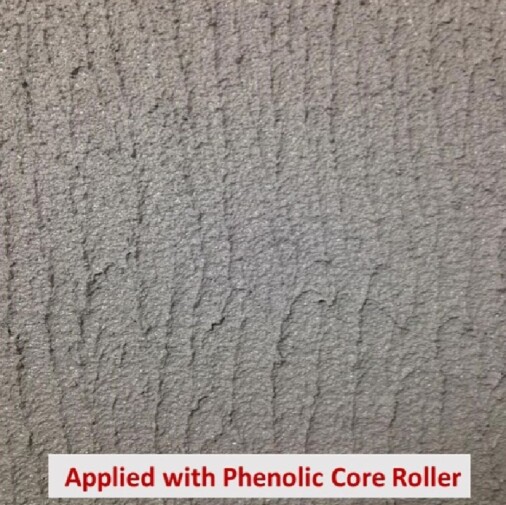

Comes in 4 colors: Light Gray, Medium Gray, Safety Yellow and Black Depending on the application, you can use a squeegee or trowel to get a smoother, less aggressive profile. Applying product with a Phenolic Core Roller offers a more aggressive surface (apply 30-40 sq’/gallon) vs flat squeegee (apply at 40-50 sq’/gallon)

PRIMER: for steel surfaces recommend E15M Epoxy Primer for best performance

TOPCOAT: Most epoxy and urethane topcoats. Note – topcoat not recommended most applications as reduces safety benefit by smoothing out texture of surface, how much depends on how thick topcoat applied.

Project Examples: DOD Navy & Coast Guard – Steel Road Plates – Airport Jet Ramp – Outdoor Wood Ramp – Trailer Wood Ramp

EXCEEDS COEFFICIENT OF FRICTION Mil-Spec PRF24667B Type 1 FOR SLIP RESISTANCE

Mil-Spec PRF-24667B Type 1 Comparison

| Condition of Coating | Dry | Wet | |

| Mil-Spec requirement | 0.90 | 0.85 | |

| E650 performance | 1.10 | 1.14 |

OSHA Non-Mandatory Standard static coefficient of friction (COF) for walking/working surfaces. (See Link): Slip Resistance. A reasonable measure of slip-resistance is static coefficient of friction (COF). A COF of 0.5, which is based upon studies by the University of Michigan and reported in the “Work Surface Friction: Definitions, Laboratory and Field Measurements, and a Comprehensive Bibliography,” is recommended as a guide to achieve proper slip resistance. A COF of 0.5 is not intended to be an absolute standard value. A higher COF may be necessary for certain work tasks, such as carrying objects, pushing or pulling objects, or walking up or down ramps.

ADA Accessibility Guidelines (ADAAG): (See Link to Appendix 4.5.1): The Occupational Safety and Health Administration recommends that walking surfaces have a static coefficient of friction of 0.5. A research project sponsored by the Architectural and Transportation Barriers Compliance Board (Access Board) conducted tests with persons with disabilities and concluded that a higher coefficient of friction was needed by such persons. A static coefficient of friction of 0.6 is recommended for accessible routes and 0.8 for ramps.

Where is the E650 used?

- warehouse floors

- Walkways and Stairs (steps)

- aisle-ways

- parking decks

- platforms

- loading docks

- Navy & Coast Guard Ship Decks

- Barge decks

- Tugboat decks

- ramps

- exterior walks

- production areas

- garages

- Seafood processing areas

- canneries

- meat packing plants

- bottlers

- poultry plants

- paper mills

- schools & public institutions

- theme parks

- oil refineries

- water treatment plants

- breweries

- wash down areas

- Ships and Work Boats

- Chemical Processing Plants

- Wet Process Areas

- Machine Shops

- Manufacturing Facilities

- Food Processing Areas

- Marinas

Why E650 Non-Skid Coating?

- Heavy duty non-skid resistance for concrete & steel surfaces

- Designed for wet areas

- Meets ADA and OSHA requirements for safe co-efficient of friction when properly applied

- Meets Navy Military Specification Mil-PRF-24667B for Non-Skid Deck Coating

- Excellent adhesion, abrasion and impact resistance

- Resistant to grease, oil, salt water, alcohol, detergent, gasoline, hydraulic fluid

- Excellent coating for Diamond Plate

- Easy to apply, ready to use non-skid coating

- Available in low temperature cure down to 25°F

- Comes in 4 colors

- E651 Non-Skid Epoxy Version Available with ZERO VOC

</tr

SPECIFICATIONS |

|

|---|---|

| Solids | By Volume 92% |

| Recommended Dry Film Thickness | 1/32″ – 1/16″ |

| VOC | 74g/L & E651 contains Zero VOC g/L |

| Colors | Dark Gray, Light Gray, Black, Safety Yellow |

| Recommended Dry Film Thickness | 1/32″ – 1/16″ |

| Coverage per Gallon | Phenolic Core Roller 30-40 sq’/gal, Trowel/Squeegee 40-50 sq’/galal |

| Packaging | 1 gallon 5 gallon (5 gallon ships LTL Freight only) |

| Mixing ratio | 4:1 by volume. Mix 4 parts Base (Part A) to 1 part Hardener (Part B) |

| Shelf Life | Part A 3 years, Part B 2 years unopened, temperature controlled |

| Coefficient of Friction | Dry 1.10, Wet 1.14 |

| Adhesion: ACI 403 | 325 psi (concrete pails) |

| Dry Heat Resistance | 160ºF ASTM D2485 |

| Thinning | 5 to 10% with SA-65 if necessary (100% MEK) |

| Clean-up | SA-74 Thinner or substitute 100% MEK Solvent |

COVERAGE RATE

| Coverage Per Gallon | Phenolic Core Roller 30-40 Sq’/Gal, Trowel/Squeegee 40-50 Sq’/Galal |

CURE SCHEDULE

Regular Cure

| Temperature | Working Time | Dry Time | Light Traffic | Heavy Traffic |

| 90ºF | 18 hours | 48 hours | ||

| 75ºF | 1-1/2 hours | 8 hours | 24 hours | 72 hours |

| 50ºF | 36 hours | 96 hours | ||

| 35ºF | na | na |

APPLICATION TEMPERATURE REGULAR CURE: 50ºF – 120ºF with relative humidity below 90%

Low Temperature Cure

| Temperature | Working Time | Dry Time | Light Traffic | Heavy Traffic |

| 90ºF | 12 hours | 36 hours | ||

| 75ºF | 1 hour | 6 hours | 18 hours | 48 hours |

| 50ºF | 24 hours | 72 hours | ||

| 35ºF | 48 hours | 96 hours |

APPLICATION TEMPERATURE LOW TEMPERATURE CURE: 38ºF – 80ºF with relative humidity below 90%

Regular cure Low Temperature application down to 45°F (air and surface low temperature during curing process). Low Temperture Cure formula available for cold weather applying to surfaces down to 38° (needs to remain at this temp or above for at least 1 hour) and then during curing process temperatures further dropping ok to as low as 25°F.

CHEMICAL RESISTANCE, SPLASH & SPILLAGE (spill contact with surface up to 72 hours)

| Aviation Gas | Hydraulic Fluid | Phosphoric Acid 20% |

| Barley Solution | Kerosene | Citric Acid 10% |

| Beer | Lactic Acid 20% | Hydrogen Sulfide |

| Calcium Chloride | Lard | Soybean Oil |

| Cutting Oil | Mineral Spirits | Sodium Hydroxide 25% |

| Fish Oil | Molasses | Wine |

| Fuel Oil | Motor Oil | Diesel Fuel |

| Gasoline | Olive Oil | Jet Fuel |

MIXING AND APPLICATION INSTRUCTIONS

SURFACE PREPARATION In all cases of surface preparation, the pH should be checked. A pH reading of 7.0 to 8.5 is acceptable. Also, a Water Dissipation Test should be made on random areas of the floor to determine if the proper degree of porosity has been achieved. Before the installation of any Gulf Coat Paint Products, the substrate should be examined for moisture. Test for moisture vapor transmission using ASTM F-1869 Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete Subfloor using Anhydrous Calcium Chloride. The maximum allowable rate is 3 lbs. per 1,000 square feet per 24 hours. Test for relative humidity in concrete floor slabs using Probes according to ASTM F-2170. This test measures the presence relative humidity of the slab below the surface. The maximum relative humidity should be below 80%.

New Concrete New concrete must be cured at least a minimum of 28 days before applying a coating. On-grade slabs must have moisture vapor barrier in place. All laitance, sealers, efflorescence, chemical contaminants, grease, oil and other foreign material must be removed. The prepared surface must be clean, dry and structurally sound. Gulf Coast Paint recommends mechanical preparation by means of shot blasting or diamond grinding to achieve a CSP-2 or CSP-3 profile, in accordance with the International Concrete Repair Institute (ICRI). The profile should reflect something similar to a 60 -100 grit sandpaper. If the substrate is not properly prepared and the appropriate profile is not achieved, failure of the product to adhere to the substrate may occur.

Old Concrete Old concrete surfaces must be structurally sound. Any unsound areas must be repaired prior to proceeding with the resinous installation. For proper patching and repairing, use CF-615 and/or E1000 with graded aggregate. Remove existing paint and loose concrete by rough sanding, sandblasting, high pressure water cleaning, shot blasting or grinding. In some cases where plant conditions allow, a stripper may be used to remove excessive build-up of paints or sealers.

Steel (Diamond Plate or equivalent) Surfaces Recommend first applying a steel primer on smooth surfaces like the E100 Moisture Cured Urethane Primer and for textured surfaces like diamond plate the E15M Epoxy Steel Primer or equivalent for best long term results. Remove any scaled or loose rust.

MIXING INSTRUCTIONS E650 is prepared by mixing 4 parts Base (Part A) to 1 part Hardener (Part B) with a 400-600 RPM explosion proof variable speed drill and Jiffy mixer. E650 may be thinned 5-10% by volume with SA-65 Thinner Solvent if necessary (100% MEK). Thinning will decrease the non-skid profile. Use immediately after mixing, no induction time is needed. This material has a high viscosity – mix well. Improper mixing may result in product failure.

For best mixing results and proper blending of parts A and B, recommend a Jiffy Mixer style drill mixer. NOTE: Always wear protective gloves and clothing while mixing and applying E650. Do not get on skin.

Use of an improper drill mixer can result in streaking of the color because the pigment has not been thoroughly blended. It can also create curing problems if the hardener also called activator (Part B) is not thoroughly blended with the resin (Part A) which can cause some areas on your floor to remain soft and not harden properly. DO NOT USE A PAINT MIXER. Many mixing problems described above can be traced back to using a paint mixer.. DO NOT HAND MIX as this approach can also result in the same problems as using a paint mixer.

APPLICATION PROCEDURE Do not apply until surface has been properly prepared. For best results, prime concrete with E5015 or HyperPRIME Concrete Primer. For priming steel surfaces, use the E15M Epoxy Mastic. Allow primer to cure before applying E650. E650 should be applied with a Phenolic Core Roller, Flat Blade Squeegee, or trowel. A phenolic core roller cover produces a textured and uniform ridged surface. If a smoother surface is desired, use a trowel or a flat blade squeegee. Immediately after mixing pour a ribbon the E650 on to surface. The ribbon should be approximately 2-3 feet long and 6 inches wide.

When using a Phenolic Core Roller pull the material towards you using some pressure. Do not over roll material this can decrease the non-skid. Roll material only in one direction. Strike off any excessive material build-up on edges from roller lap. The spread rate is approximately 30-40 sq. ft. per gallon.

When using a squeegee or trowel, hold on 45º angle pulling material toward you. Pour a 2-3 inch wide ribbon. Apply at an even thickness at an approximate coverage rate of 40-50 sq. ft. per gallon.

For safety and proper product curing, good ventilation is necessary when painting indoors or in confined areas. Be sure the batch numbers are all the same to provide uniform color. Epoxy coatings may yellow or darken during application and after final cure. This will affect the color but will have no effect on the performance of the product. Heaters that emit carbon dioxide and carbon monoxide can cause the coating to yellow

CAUTIONS E650 Base is flammable. E650 Hardener is corrosive. Keep away from all sources of ignition during mixing, application and cure. The HARDENER and BASE can cause eye and skin burns as well as allergic reactions. The use of goggles, fresh air masks or NIOSH approved respirators, protective skin cream and protective clothing. This product is sold without warranty as to performance expressed or implied. Users are urged to make their own tests to determine the suitability for their particular conditions.

LIMITATIONS:

- Do not apply over frost, wet or damp surfaces or extremely high humidity conditions.

- Do not apply over expansion joints.

- Do not apply if the surface temperature is within 5° of the dew point.

- Always apply a test patch of E650 for owners approval prior to application

- Partially used containers must be reclosed tightly to prevent moisture in air from reacting with material and forming a tough skin. Skin can be removed and remaining material used. Be sure to stir.

Refer to the cure schedule as a guideline to follow, in addition we strongly recommend to test the coating before recoating or topcoating. This is done by pressing your thumb on the coating in multiple places to ensure a fingerprint impression is not visible. If there is no impression visible, then coating the floor can be done. Note, colder or hotter than 75 degrees can affect the curing time schedule

SEE MATERIAL SAFETY DATA SHEET FOR FULL SAFETY PRECAUTIONS. FOR PROFESSIONAL AND INDUSTRIAL USE ONLY KEEP AWAY FROM CHILDREN. NOT FOR RESIDENTIAL USE NOTICE TO BUYER: DISCLAIMER OF WARRANTIES AND LIMITATIONS ON OUR LIABILITY We warrant that our products are manufactured to strict quality assurance specifications and that the information supplied by us is accurate to the best of our knowledge. Such information supplied about our products is not a representation or a warranty. It is supplied on the condition that you shall make your own tests to determine the suitability of our product for your particular purpose. Any use or application other than recommended herein is the sole responsibility of the user. Listed physical properties are typical and should not be construed as specifications. NO WARRANTY IS MADE, EXPRESSED OR IMPLIED, REGARDING SUCH OTHER INFORMATION, THE DATA ON WHICH IT IS BASED, OR THE RESULTS YOU WILL OBTAIN FROM ITS USE. N0 WARRANTY IS MADE, EXPRESSED OR IMPLIED, THAT OUR PRODUCT SHALL BE MERCHANTABLE OR THAT OUR PRODUCT SHALL BE FIT FOR ANY PARTICULAR PURPOSE. NO WARRANTY IS MADE THAT THE USE OF SUCH INFORMATION OR OUR PRODUCT WILL NOT INFRINGE UPON ANY PATENT. We shall have no liability for incidental or consequential damages, direct or indirect. Our liability is limited to the net selling price of our product or the replacement of our product, at our option. Acceptance of delivery of our product means that you have accepted the terms of this warranty whether or not purchase orders or other documents state terms that vary from this warranty. No representative is authorized to make any representation or warranty or assume any other liability on our behalf with any sale of our products. Our products contain chemicals that may CAUSE SERIOUS PHYSICAL INJURY. BEFORE USING, READ THE SAFETY DATA SHEET AND FOLLOW THE PRECAUTIONS TO PREVENT BODILY HARM.

Installing E650 (Phenolic Core Roller)

Installing E650 (Flat Blade Squeegee)

Check out our customer projects using the E-650 Epoxy!

Chilean Warship Installs E-650 Non Skid Deck Coating

Florida Airport Protects Jet Ramps with E650 Non-Skid Epoxy

Little Rock VA Healthcare Facility Protects Wooden Wheelchair Ramp with E-650 Non-Slip Epoxy

Aluminum Oxide Anti-Slip | WHITE | 4 Grit Sizes | Non-Skid Tough Durable Floor

From: $65.00- Adds very tough, durable skid resistance & texture profile to surface

- Epoxy, Polyaspartic, Urethane 2 component coatings

- Does not change physical properties of the coating

- Well bonded into the body of the coating

- Excellent in marine environments

- White color can be used with clear coatings and decorative floors using chips

- Variety of grit sizes from 16 extra coarse to 54 medium

- High hydrolitic stability

Aluminum Oxide High Wear Abrasion Resistant Additive | 220 Grit | 325 Grit for Urethane & Polya...

From: $31.00- Significantly improves abrasion resistance of floor coatings

- Helps create a tough, durable, abrasion resistant surface

- Simple and easy to add while mixing a coating

- Works with any urethane and thin film polyasprtic coating

- Works well with high performance 2 part floor coatings

- Does not change physical properties of the coating

- Well bonded into the body of the coating

- High hydrolitic stability

- White Color in options 220 grit and 325 grit

Anti-Slip Glow Sand | Aqua, Blue & Green | Photoluminescent for Floor Coatings | Glows to 8+ Ho...

From: $38.00- Create anti-slip texture for a slip resistant floor surface with a great looking, long lasting green glow when lights are off

- Largest particle size green "Glow in the Dark Sand" at 30 grit (500 microns)

- Anti-Slip Glow Sand comes in Green (30 grit), Blue (65 grit) and Aqua (110grit)

- Brightest and longest lasting glow pigment

- Ideal for use with epoxies, polyaspartics, urethanes and polyurethanes

- Mix with clear epoxies and concrete sealers to create glow in the dark floors

- For use in both indoor and outdoor projects.

- Settles well to the bottom of cracks and grooves in glow in the dark tables and other wood projects when mixed with epoxy

- Creates an abrasive glow in the dark texture when applied in very thin layers

- Glow Sand Sample Kit Offered in all 3 colors

E1016 Anti-Slip Epoxy Concrete Floor Coating – 3 Gal Kit | 20 Colors | Tennis Court Like Surfa...

From: $58.00- Adds a slip resistant finish to concrete floors

- Good for use on surfaces subject to bare foot traffic

- Long 1 - 1.5 hour pot life

- Excellent adhesion

- Good chemical and abrasion resistance

- Wide selection of clear plus 20 color options

- Water base

E650 Non-Skid Epoxy Floor & Deck Low Temp 25°F | OSHA ADA Navy Spec Mil-PRF-24667B Type 1 | 4 Co...

From: $107.00- Heavy duty non-skid resistance for concrete & steel

- Available in regular cure and cold temp formula to 25°F

- Designed for wet areas

- Meets ADA and OSHA requirements for safe co-efficient of friction (COF) when properly applied

- Meets Navy Military Specification Mil-PRF-24667B for Non-Skid Deck Coatings

- Excellent adhesion, abrasion and impact resistance

- Resistant to grease, oil, salt water, alcohol, detergent, gasoline, hydraulic fluid

- Excellent coating for Diamond Plate

- Easy to apply, ready to use non-skid coating

- Comes in 4 colors

- E651 Non-Skid Epoxy Version Available with ZERO VOC

E814R Co-Polymer Liquid Rubber Roof Walkway Coating | Slip Resistant

From: $195.00- Exceptionally tough, durable one part waterproof roof walkway

- Offers excellent anti-slip walking surface

- Excellent adhesion EPDM, APP, TPO, Hypalon, Concrete, Wood, Metal

- Available in 12 colors

- Excellent waterproof with E96 Vapor Transmission Class I 0.025 perms and Water Absorption 0.04%

- Excellent weathering

- Excellent UV stability

- Good resistance to dirt pickup

- Excellent low temp flexibility with 500%+ Elongation

- Resists mildew and fungi growth

- Good resistance to Alkalis and acids

EZ-Coat Textured Acrylic Coating | Metal, Wood, Concrete | Textured Finish | Scratch Resistant

From: $60.00- Excellent flow rate for an Easy application

- Flexible and not brittle

- Easy to touch up or maintain

- Low Odor

- Low VOC

- Scratch Resistant Finish

- Protects Substrates from weathering - UV & Moisture

- Textured Finish

- Interior and Exterior Surfaces

Garnet Anti-Slip Additive| BROWN | 36 Grit | Non-Skid Tough Durable Floor

From: $35.00- Adds very tough skid resistance & texture profile to a surface

- Works well with high performance 2 part pigmented floor coatings

- Non-reactant – will not interfere with your coatings

- Well bonded into the body of the coating

- Long lasting for extended anti-slip performance

- Cost–effective – highly effective

- Non-toxic – inert and natural, crystalline silica levels are less than 1%

- Comes in the most popular 36 grit size

- Low Cost alternative to white colored aluminum oxide for only slightly less level of anti-slip performance

Polybead Anti-Slip Additive | Least Change Appearance | Easy to Clean & Use | 2 Grit Sizes

$32.00- Adds skid resistance & texture profile to a surface

- Least Change in Surface Appearance & Easiest to Clean

- Use with Epoxy, Polyaspartic, Urethane, Polyurethane and most coatings

- Very small amounts required

- Lightweight aggregate, blends well into coating

- Does not have to be surface broadcast over coating

- Does not change physical properties of the coating

- Reduces surface dirt accumulation for easy cleaning

- Appearance better than sand

- Can be used on decorative floors using chips

- Excellent in marine environments

- High hydrolitic stability

Silica Sand Anti-Slip Additive For Epoxy, Polyaspartic, Polyurethane, Urethane Floor Coatings | 5 Si...

From: $29.95- Adds very tough skid resistance & texture profile to a surface

- Works well with high performance 2 part floor coatings

- Does not change physical properties of the coating

- Well bonded into the body of the coating

- Comes in 5 mesh sizes

Quantity Discounts AvailableSOLD IN 4 lb, 44 lb & 50 lb BAGS

Reviews

From: $55.00

From: $120.00

Related products

E1409CL Moisture Vapor Barrier Epoxy Sealer Primer For Concrete ASTM F3010

From: $247.00- Reduce effects of moisture vapor transmission on concrete floors

- Control moisture vapor emission rates to 20 lb/24hr/1000 sq' (ASTM F1869)

- Used as Sealer/Primer to protect Polymeric coating systems, vinyl sheets, tile, cementitious overlays, terrazo, wood veneers, and carpet

- 100% solids with 0 voc

- Easy to apply with one coat most projects

- Meets ASTM F3010 for vapor permeance at the recommended thickness

| Weight | N/A |

|---|---|

| Dimensions | N/A |

E-Poly Pigment For All Floorguard Epoxy & Polyaspartic Coatings | 12 Colors

From: $52.00- Universal E-Poly Pigment Designed to Color All Epoxy & Polyaspartic Coatings manufactured by Floorguard Products

- Add a Beautiful Decorative Color to Your Epoxy Project

- 12 Different Colors to Choose From!

- Sold in Quart Containers - Typically colors 3-5 Gallons When Mixed Into Clear Epoxy or Polyaspartic

- 2 Gallon Containers Available in Select Colors

- Pigment can be Pre-mixed into Floorguard Epoxy & Polyaspasrtic Coatings on all orders 60 gallons or more with 4-7 days lead time (when ordered in 10 or 15 gallon kits as appropriate)

| Weight | N/A |

|---|---|

| Dimensions | N/A |

HyperFLEX Epoxy | Flexible Membrane Concrete Wood Steel | 150% Elongation | Low Temp 40°F | Quick Cu...

From: $74.00- Tough, Durable Epoxy Coating and Flexible Membrane

- Very Flexible with Elongation rating 150% @ASTM D-638

- Great for Quick Crack Repair and Control Joint Filler (when mixed with Fumed Silica)

- Can be used as a (1) basecoat for full broadcast floors, (2) flexible membrane, (3) repair gel to fill joints, cracks, & divots

- Cold temperature application down to 40°F

- Concrete & Wood Floors and Countertops

- Superior Flexibility and Outstanding Bonding

- Rapid Cure Rate For Same Day Flake and Solid Color System Application (recoat 2 hours at 75F)

- When used as membrane or basecoat HyperFLEX cures about 2 hours

- When used for gel repair cures about 10-15 minutes

- Good chemical and abrasion resistance

- High solids 100%

- Withstands up to 9 lbs. of hydrostatic pressure

- Available in clear & 13 colors! (Pigment sold separately)

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Size |

E130A Oil Contaminated Concrete & Asphalt Epoxy Mortar Patch Kit/Resurfacer

From: $66.00- Great for patching and repairing oil contaminated and damaged concrete

- Can be used to patch and repair asphalt surfaces

- Can be applied up to 1/8" one application

- Crack. holes and general surface repairs

- Excellent abrasion and impact resistance

- 100% solids

- Easy to Use 3 part kit Includes Silica Sand or Liquid Only

| Weight | N/A |

|---|---|

| Dimensions | N/A |

Copyright 2024 by Exterior Performance Coatings LLC