No products in the cart.

Return To ShopProduct Description

800 Slow Set Polyurea Sealant Adhesive & Caulk

800 Polyurea Adhesive Sealant & Caulk is a 100% solids, thick, flowable chemical and fuel resistant, quick set reactive gel polymer compound used as an adhesive material for various substrates including metals, plastics and concrete.

It is used in a wide variety of applications including the sealing of plastic connectors, fittings and repair of concrete floor cracks in severe use environments against severe chemical, caustic and physical environments, abrasion, thermal shock and corrosive fumes, steam & hot water. The 800 can be applied to a wide variety of substrates including metals, plastics, fiberglass, steel, wood, urethane, polyurea and concrete.

The 800 offers quick back in-service time of 1 – 1.5 hours. The 800 retains its flex even in thick applications, is not brittle and can be sanded and painted in a short period of time.

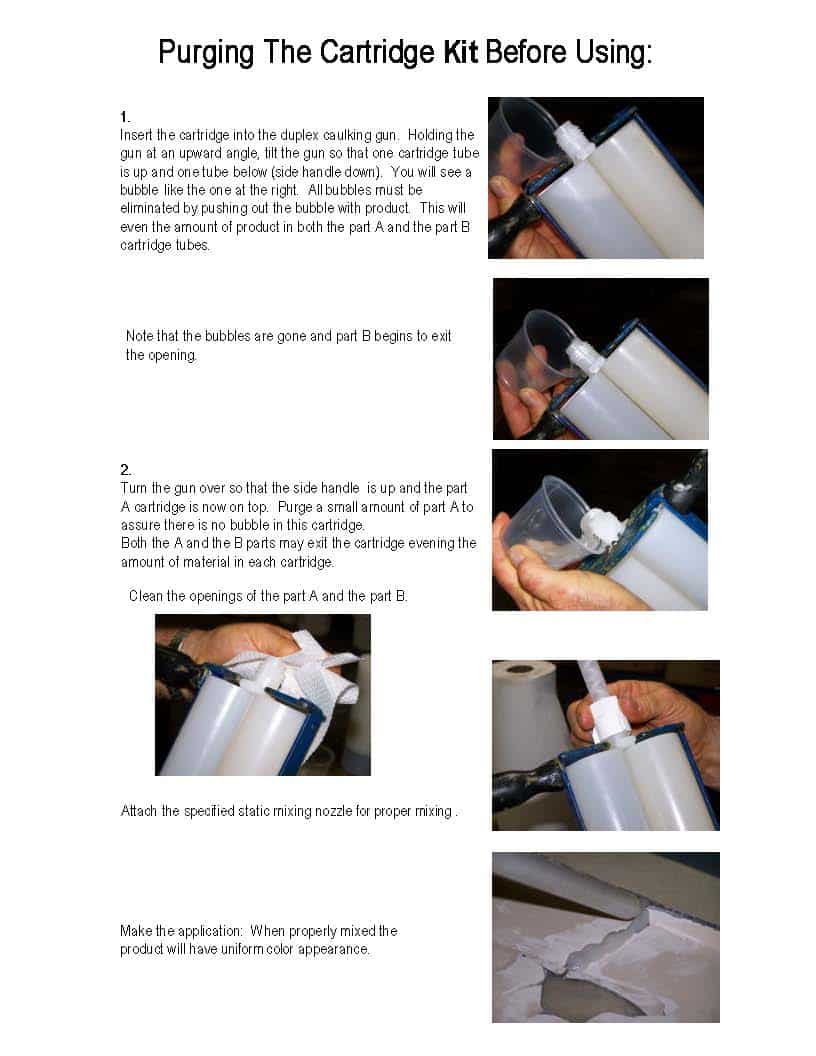

800 is dispensed from a duplex cartridge or plural component pump. Available in non-pigmented white color (call for special order in black color), in dual cartridges kits (21 oz or 600 ml total product in one cartridge kit – requires dual cartridge dispensing gun), 2 and 10 gallon kits (equal part A/B). Special order 100 gallon kits available.

Where is the 800 Polyurea used?

- Use with 7001 Polyurethane Primer when moisture orhigh humidity is present for better performance

- Immediate crack and damage repair for decorative floors

- Fiberglass bonding and repair

- Tank seam sealing

- Sealing plastic fittings & connectors

- Seam bonding filling for tanks, ducts and wall panels

- USDA Food processing areas – concrete floor repair

- Vertical Surfaces – sealing and repair

- Used as caulking, filling, bonding and self-leveling applications

- Waste holding & treatment areas – sealing and repair

- Petrochemical production floors

- Pulp and paper

- Waste Treatment facilities

- Repair of high traffic industrial floors

Why 800 Polyrea Adhesive & Caulk?

- Back in-service 1 – 1.5 hours, recoat 30-45 minutes, full cure 6-8 hours

- High chemical & fuel resistance

- Highly adhesive to many substrates

- Good working time, quick gel time 6-10 minutes, trowel-able

- Cartridge or pump dispensed

- Can be sanded and painted over

- Fast set, trowel-able

- 100% solids, no VOC, no odor

- Option for easy application using twin cartridge kits and 300 ml x 300 ml cartridge gun