No products in the cart.

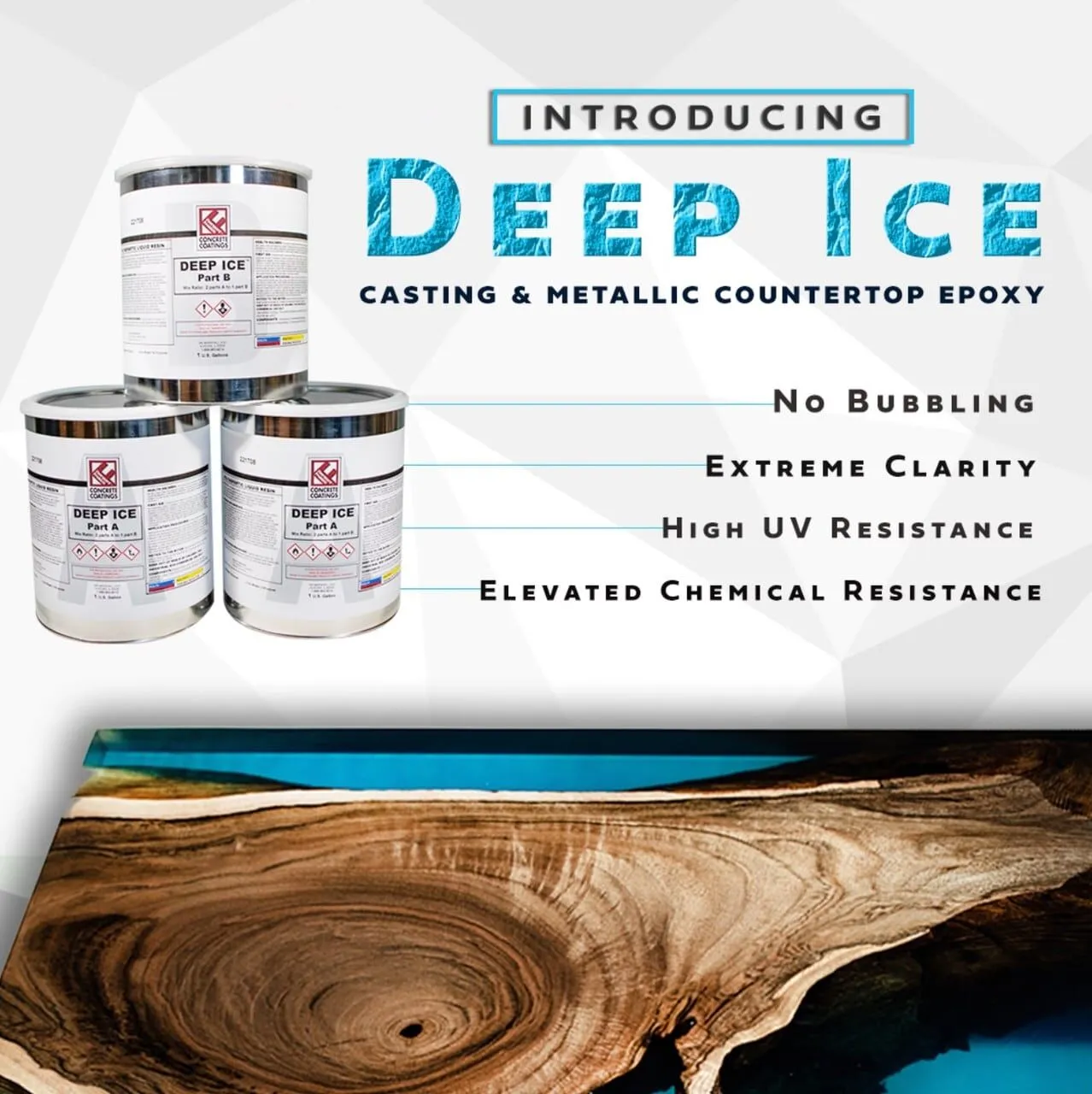

Return To ShopDeep Ice Countertop and Casting Epoxy | River Tables | Bar Tops | To 4″ Deep | Bubble Free

Deep Ice is a 100% solids, professional grade hybrid epoxy resin used for casting projects, metallic counters, and embedding objects. This extremely clear resin can be poured up to 4 inches thick at one time, is very UV resistant and has phenomenal structural strength, chemical resistance, and is bubble free.

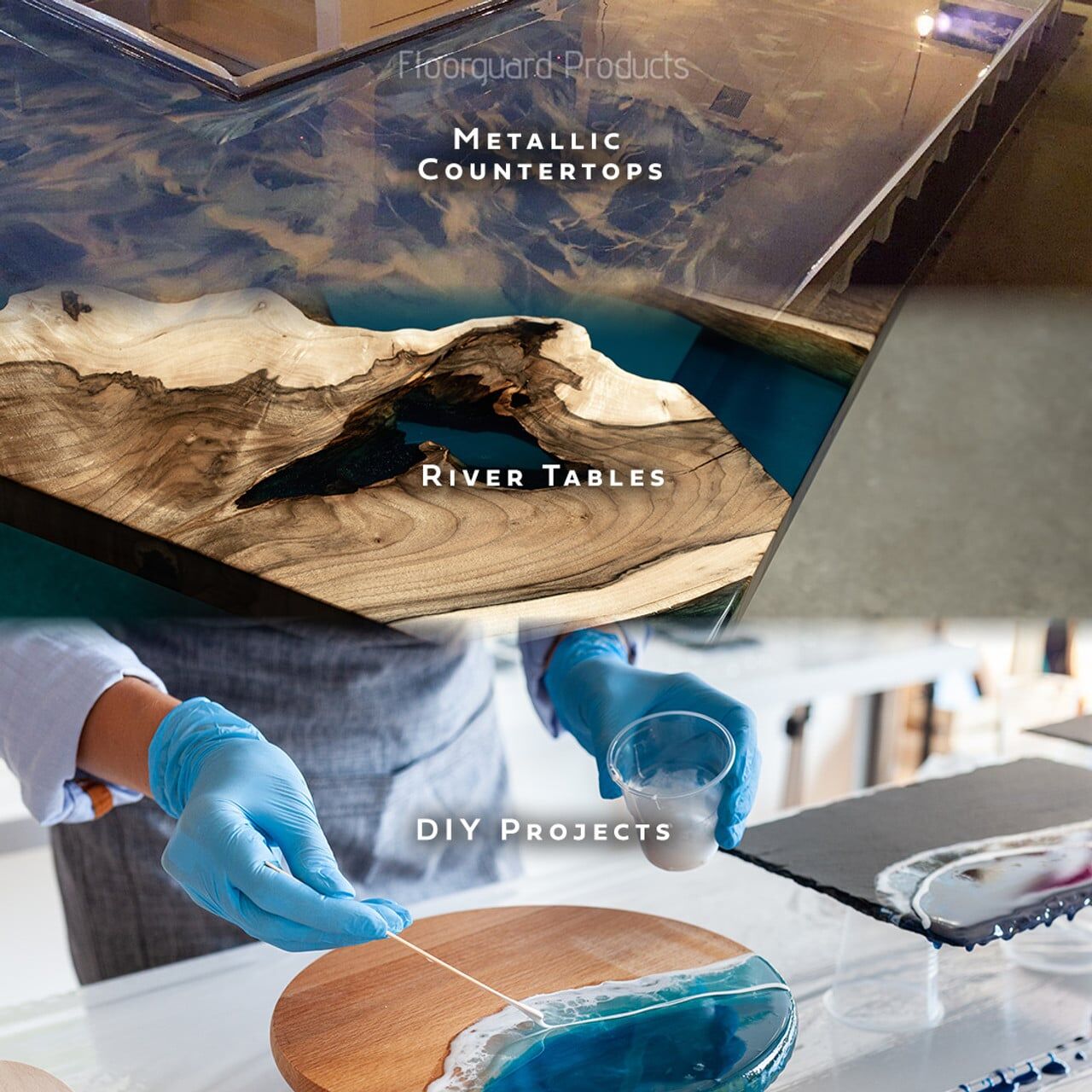

Deep Ice is ideal for a wide variety of projects including river tables, bar tops, metallic counters, or any DIY project. Mica pigments, epoxy pigments or dyes can be used with Deep Ice.

Deep Ice comes in clear or can be tinted with one of our 50 Metallic Epoxy Pigments (pigment sold separately in 4 oz containers) for a dramatic 3-D look.

Deep Ice is sold in 24 oz sample kits and 3 gallon kits of clear product.

What does 1 gallon Deep Ice Epoxy cover?

1/8″ thick = 12,8 sq’

1/4″ thick = 6.4 sq’

1/2″ thick = 3.2 sq’

3/4″ thick = 2.3 sq’

1.0″ thick = 1.6 sq’

1.5″ thick = 1.1 sq’

2.0″ thick = 0.8 sq’

2.5″ thick = 0.6 sq’

3.0″ thick = 0.5 sq’

3.5″ thick = 0.46 sq’

4.0″ thick = 0.4 sq’

PRIMER: None needed.

TOPCOAT: Can apply clear coat of urethane or polyaspartic coating including Aspartic 85

Where is Deep Ice Countertop and Epoxy used?

- Kitchens

- Countertops

- River tables

- Bar tops

- Metallic counters

Why Deep Ice Epoxy

- Easy Application

- No need to use torches or vacuum chambers

- Bubble Free

- See-through clarity

- Looks great with Metallic and Mica pigments and Dyes

- Can be poured up to 4” thick in one pour

- Excellent UV & Chemical Resistance

- Superior Structural Strength: Withstands 2,000 lbs/sq.in pressure for up to (30 minutes of exposure)