No products in the cart.

Return To Shop3004 Polyurea Fast Set Joint Filler For Control Joints

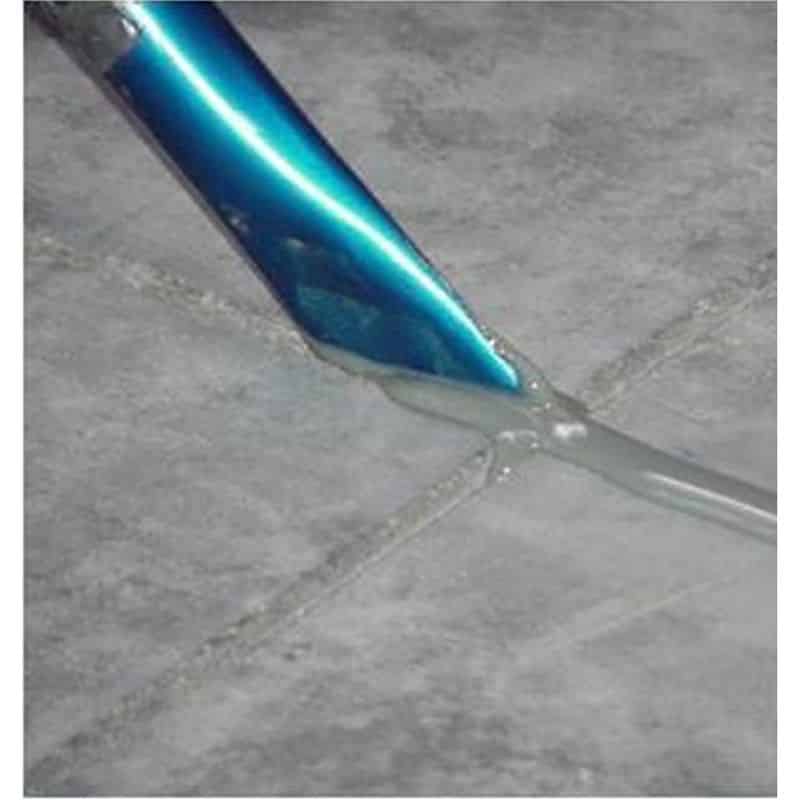

3004 is a very fast setting, high performance 2 part 100% solids, flexible Polyurea joint filler designed for interior concrete control joints requiring a tough, durable chemical, fuel and highly abrasion resistant solution. 3004 is designed specifically for commercial, retail, warehouse and manufacturing floor applications which receive high volume vehicle traffic, such as fork lift or hard rubber wheel carts that can’t afford downtime, 3004 offers quick 20-30 minute back in-service times. Ideal for use with high speed machine dispensing system.

3004 can be used in very cold -20°F (-29°C) temperature applications such as cold storage areas which limit the use of other polymer products. Just need to keep the 3004 warm until ready to apply. 3004 provides “load transfer” across standard concrete saw cut control joints. When a primer is desired prior to application of the 3004, use the 7001 Polyurethane Primer.

3004 is on the Costco master specs in CSI Division 3 as a polyurea joint filler for both new construction and maintenance repair of interior floor control joints.

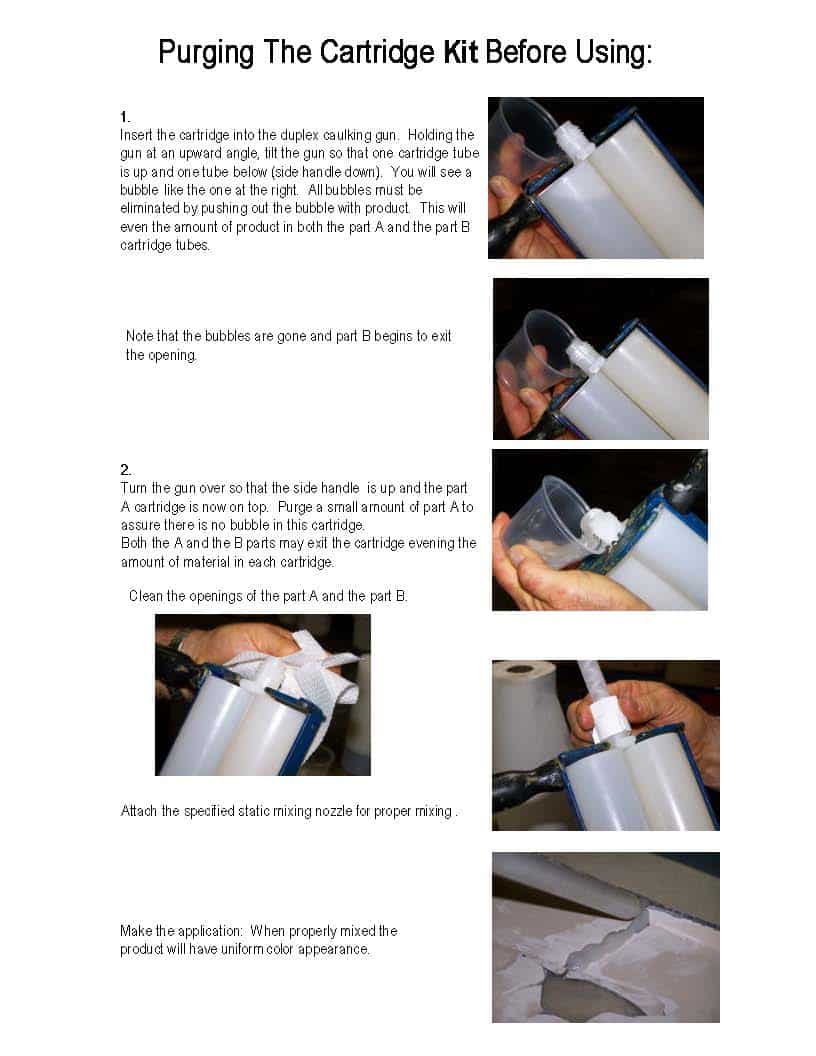

3004 comes in a dark gray color. Available in 2 gallon and 10 gallon kits for use with our US Saws Plural Component Pump or dual cartridges (21 oz or 300 ml x 300 ml cartridge kit) with static mixer using a dual cartridge gun (manual, air or electric). For “Hand Mixing” see our 3003 Slow Set Polyurea.

For outdoor control joint applications such as driveways, use our 3246 Polyurea Expansion Joint product offering 600% elongation and soft Shore Hardness of A30-40. It’s great for handling thermal cycling and temperature variations of outdoor environments.

Where is the 3004 Polyurea used?

- Control Joints – Interior Concrete

- Garages

- Warehouses

- Offices

- Cold Storage – Freezer Thresholds

- Utility Cuts

- Cable Runs & Inductive loops

Why 3004 Fast Set Polyrea Control Joint Filler?

- Quick Back-in-Service “Drive-Over” in only 20-30 minutes

- Offers load transfer across control joints for good protection of edges

- Ideal for High Speed Application using Machine Dispensing System or for small projects easy application using twin cartridge kits and 300 ml x 300 ml cartridge kits (total 21 oz or 600 ml per cartridge kit)

- Tack Free only 2-3 minutes

- Meets USDA Requirements for incidental food contact

- Stays Flexible In Extreme Cold with 300% Elongation

- Cold Applications down to -20°F (-29°C)

- Not Sensitive To Moisture

- Non-Flammable

- Self-leveling

- High Impact Resistance

- Excellent Abrasion Resistance

- Chemical Resistant

- 100% Solids, No VOC, No Odor