No products in the cart.

Return To ShopProduct Description

3246 Polyurea Flexible Quick Cure Joint Filler for Expansion Joints | 600%+ Elongation

3246 Polyurea Expansion Joint Filler is an extremely flexible, 600%+ elongation, high performance 2 part 100% solids joint filler designed for all interior and exterior expansion joints and outdoor control joints requiring a high density, extremely flexible, chemical, fuel and abrasion resistant solution. It offers a quick 30-45 minute back in-service time for high value applications that can’t afford downtime including parking structures, driveways, walkways, bridges, airfield joints and a wide variety of industrial, commercial and infrastructure applications.

The 3246 can also be used in very cold below zero temperature applications to -20°F which limit the use of other polymer products such as cold storage facilities or outdoor winter projects. Just need to keep the 3246 warm at room temperature until ready to apply.

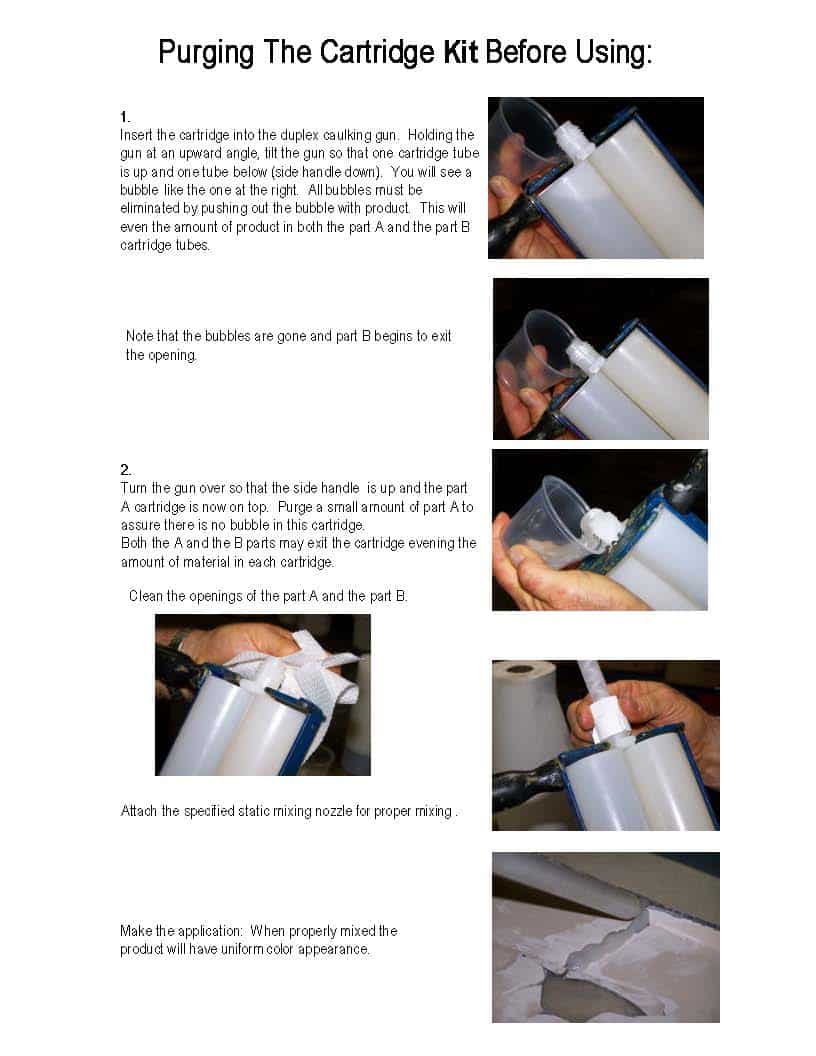

3246 is a self-leveling, 100% solids polyurea joint repair with no VOC’s and offers excellent resistance to moisture, chemicals and abrasive conditions. It is machine dispensed using twin component joint filler dispensing machine. It can also be applied manually in a twin cartridge configuration using a twin cartridge gun. Moving joint repairs require a primer application within one hour of the 3246 application.. Use the 7001 Polyurethane Primer.

3246 is on the Costco master specs in CSI Division 3 as a polyurea joint filler for both new construction and maintenance repair of interior floor expansion joints.

Available in 2 gallon, 10 gallon, 110 gallon drum kits kits for use with 2 component machine dispensing system such as the US Saws Model SX2000, or by hand using dual cartridge kits (21 oz or 600 ml total product per kit) with static mixer for dispensing using a Manual or Pneumatic Cartridge Gun. 3246 comes in a standard dark gray color. Black, tan and non-pigmented available special order. Call for details.

***MAY BE 1-3 WEEK LEAD TIME BEFORE SHIPPING. PLEASE CALL 630.675.4509 FOR SPECIFICS****

Where is the 3246 Polyurea used?

- Driveways

- Walkways

- Loading docks

- Moving expansion joints

- Parking structures

- Bridges

- Airfields (Meets FAA P605)

- Decks

- Cold storage thresholds

- Expansion Joints – interior/exterior concrete

- Control Joints – exterior concrete

Why 3246 Polyrea Expansion Joint Filler?

- Quick set with “Drive-Over” in 30 to 45 minutes

- High Density Polyurea

- Very Flexible with Elongation ASTM D124 >600%

- Meets USDA Requirements for intermittent contact

- Meets FAA P605 – for airfield joints

- Stays Flexible even in cold conditions

- Low Temp application down to -20°F

- Self-leveling

- Excellent Abrasion Resistance

- High Impact Resistance

- Chemical Resistant

- 100% Solids, No VOC, No Odor

- Apply using High Speed Machine Application and for small projects easy application using twin cartridge kits and 300 ml x 300 ml cartridge gun