APPLICATION INSTRUCTIONS

Preparation

Concrete must have a minimum 28 day cure prior to application. Use a dry diamond saw, saw/abrade both sides of the joint walls. Assure that the joint is properly abraded and cleaned to full depth, approximately 1.25 inches as a standard depth of fill. Remove any curing agent, form release materials, oils, wax, moisture or any material that may affect bonding.

Clean, vacuum and wash to remove dust from the walls of the joint. Wash-down is suggested for concrete surface that will be constantly surface-washed as part of the operation of the facility. An acetone joint side wall wash-down is suggested for best bonding after vacuuming. No Backer rod is used in control joints, only in construction joints to control depth.

*Areas of high moisture vapor may be pre-treated with CMW 8000 (see data sheet) to reduce moisture vapor pressure in the joint area.

Application

The 3004 sets too fast to be used without application using either twin cartridge or dual component pump application system.

Use a 1:1 application machine such as or equal for 2 gallon and 10 gallon kits. If not available, apply using dual 10.5 oz cartridges (21 oz total per cartridge kit) and dual cartridge gun which can be manual, pneumatic or electric operated. Make sure the product is over 72°F before beginning the machine application. Warm the product in the containers as needed to pre-condition as required. Use ONLY the ASTC recommended mixing wand for this product. Failure to use proper mixers may result in improperly mixed product and/or poor curing. Use two 1/2 x 36 inch element static mixers connected with a 1/4 inch pipe nipple and a metal joint “tracker” on the end of the static mixer.

Note: Aromatic systems will shift color from exposure to UV. Dark color resists color change more than light colors. Aliphatic top coats are often used to provide stable color.

IMPORTANT

MIXING ORDER – Jiffy Mixer and Drill Motor Mixing Part A must be in the mixing pail first and the jiffy mixer MUST be moving and mixing the part WHILE the equal amount of Part B is evenly poured into the moving part A. DO NOT reverse this mixing order. Once Part B has been added to the moving Part A, mix the A & B at full speed, moving the Jiffy mixer up, down and around the mixing pail. Mix for no more than 60 seconds, then pour into application IMMEDIATELY —DO NOT WAIT.

Improper mixing may result in product failure.

For best mixing results and proper blending of parts A and B, recommend a Jiffy Mixer style drill mixer.

General Application Instructions

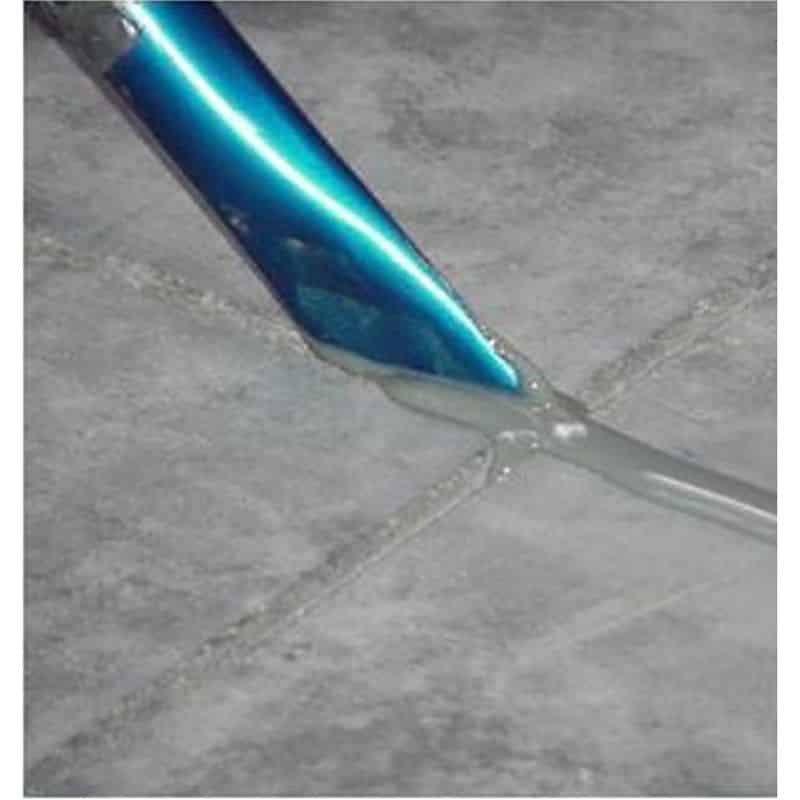

Fill the joint from the bottom up will help reduce air bubbles in the final product by allowing them to rise into the overpour. Make the application in the joint with a slight over-pour. Trim the over-pour from the joint area about 15 to 20 minutes after installation. Use a very sharp razor cutter to make the cut. Cutting too soon will leave a poor surface finish as the product may be gummy, while cutting too late could produce a chattered appearance over the surface of the cut product. Monitor the in-place product and do several test cuts then cut when it is ready.

There is no standard set time for the product in cold temperatures. Cold conditions/temperatures vary. Once the product is installed in the joint it must be monitored to determine the best time for surface shearing/cutting. For extreme cold conditions a heat gun can be used to warm product prior to cutting.

Note on cutting: When the 3004 has set and is cut at the suggest time it should cut with less effort than if it is cut after an hour or more. Take care when cutting the product in joints that are wider than standard saw cut control joints, that is, when cutting a wide joint use a slicing action on the cutting rather than a straight on push. ** If a lot of down-ward pressure is exerted on the cutting tool on large joints the razor blade can flex down into the joint and produce a joint surface that is slightly below grade. This is why a slicing action can be helpful, cutting at the right time is suggested and if possible use a non-flexing blade.

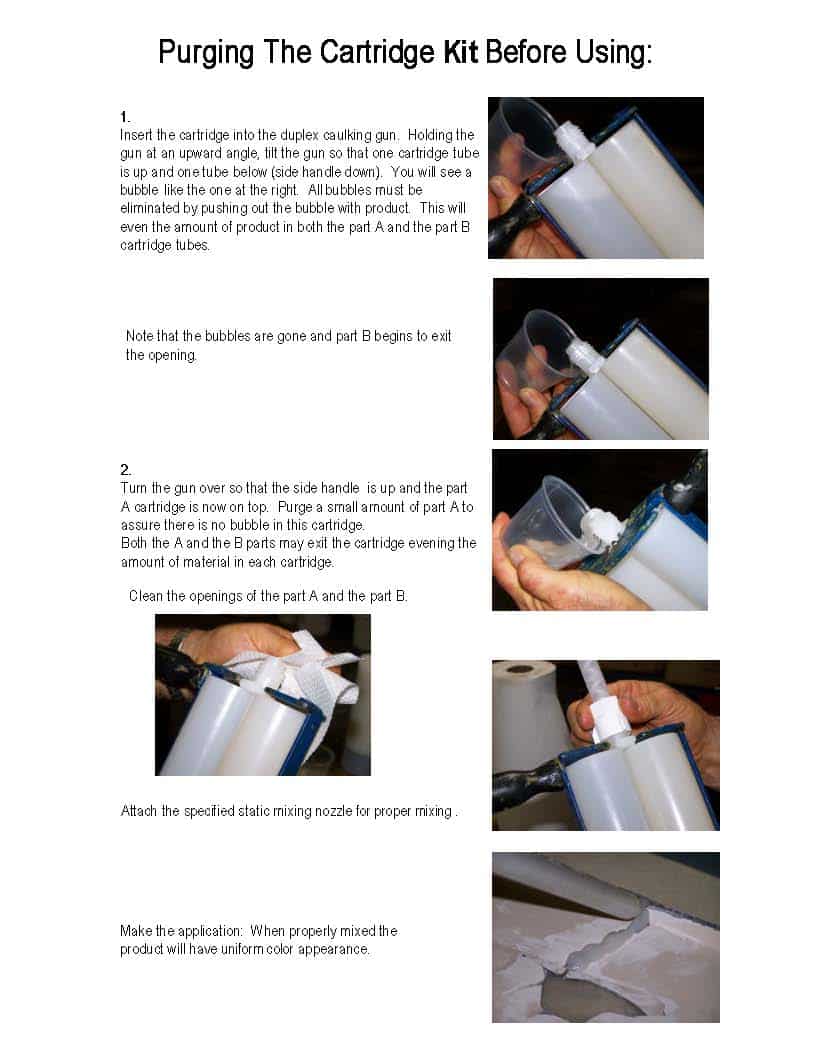

Cartridge Use:

3004 is packaged in 300 x 300 ml duplex cartridges. This cartridge uses a standard Manual Duplex Caulking Gun. Use ONLY the ASTC recommended static mixer for this product. Failure to use proper mixers may result in improperly mixed product and/or poor curing.

1:1 Ratio Machine Application

Use a 1:1 application machine such as Us Saws Plural Component Pump or equal. Make sure the product is over 72°F before beginning the machine application. Warm the product in the containers as needed to pre-condition as required.

Cold Temperature Application

3003 may be used in cold temperature applications well below zero °F. Set times change very little in cool temperatures and flexibility is maintained.

Cold Applications

When using this product in below zero applications, keep the product and equipment warm, and warm the product to 80°F- 90°F before using.

Temperature & Dehydration

It is important to note that for the best allowable joint performance the temperature of the slab should be considered during the application. It is always important to have the building area, office, warehouse, industrial area or cold storage at its working temperature before filling the control joints. Filling the control joints in warm conditions then reducing the temperature via air condition will produce additional shrinkage to the slab and the joint area via additional dehydration by the air conditioner and the cool of the slab. This effect is dramatic for cold storage facilities. The 3003 when used in cold storage should be applied at the facility’s working temperature.

Joints should not be filled in direct sunlight or while the slab is hot. Hot slabs have closed control and expansion joints. The joints of a building slab should be filled when the building is enclosed. For best results the joints should be filled at the working temperature of the building. This is important in areas where the ambient temperature and humidity is high. In warm or hot environments bring the temperature via air conditioning to working temperature then fill the joints. Failure to fill joints at working temperatures may result in bond rupture.

Moisture Vapor Reduction

3004 is compatible with CMW 8000 used in joints to reduce moisture vapor pressure on joint products.

Limitations

Do not use on wet surfaces or expose part A to moisture. Keep out of direct sunlight and store ten gallon kits on wood pallets at room temperature. Warm product kits on pallets before using. Protect from cold conditions when using this product in cold storage. Always mix part B before using.

NOTICE TO BUYER: DISCLAIMER OF WARRANTIES AND LIMITATIONS ON OUR LIABILITY We warrant that our products are manufactured to strict quality assurance specifications and that the information supplied by us is accurate to the best of our knowledge. Such information supplied about our products is not a representation or a warranty. It is supplied on the condition that you shall make your own tests to determine the suitability of our product for your particular purpose. Any use or application other than recommended herein is the sole responsibility of the user. Listed physical properties are typical and should not be construed as specifications. NO WARRANTY IS MADE, EXPRESSED OR IMPLIED, REGARDING SUCH OTHER INFORMATION, THE DATA ON WHICH IT IS BASED, OR THE RESULTS YOU WILL OBTAIN FROM ITS USE. N0 WARRANTY IS MADE, EXPRESSED OR IMPLIED, THAT OUR PRODUCT SHALL BE MERCHANTABLE OR THAT OUR PRODUCT SHALL BE FIT FOR ANY PARTICULAR PURPOSE. NO WARRANTY IS MADE THAT THE USE OF SUCH INFORMATION OR OUR PRODUCT WILL NOT INFRINGE UPON ANY PATENT. We shall have no liability for incidental or consequential damages, direct or indirect. Our liability is limited to the net selling price of our product or the replacement of our product, at our option. Acceptance of delivery of our product means that you have accepted the terms of this warranty whether or not purchase orders or other documents state terms that vary from this warranty. No representative is authorized to make any representation or warranty or assume any other liability on our behalf with any sale of our products. Our products contain chemicals that may CAUSE SERIOUS PHYSICAL INJURY. BEFORE USING, READ THE MATERIAL SAFETY DATA SHEET AND FOLLOW ALL PRECAUTIONS TO PREVENT BODILY HARM.